Explore What Are the Colored Dots on Packaging?

Waqas Khan Pitafi 2025-07-03 06:44:10

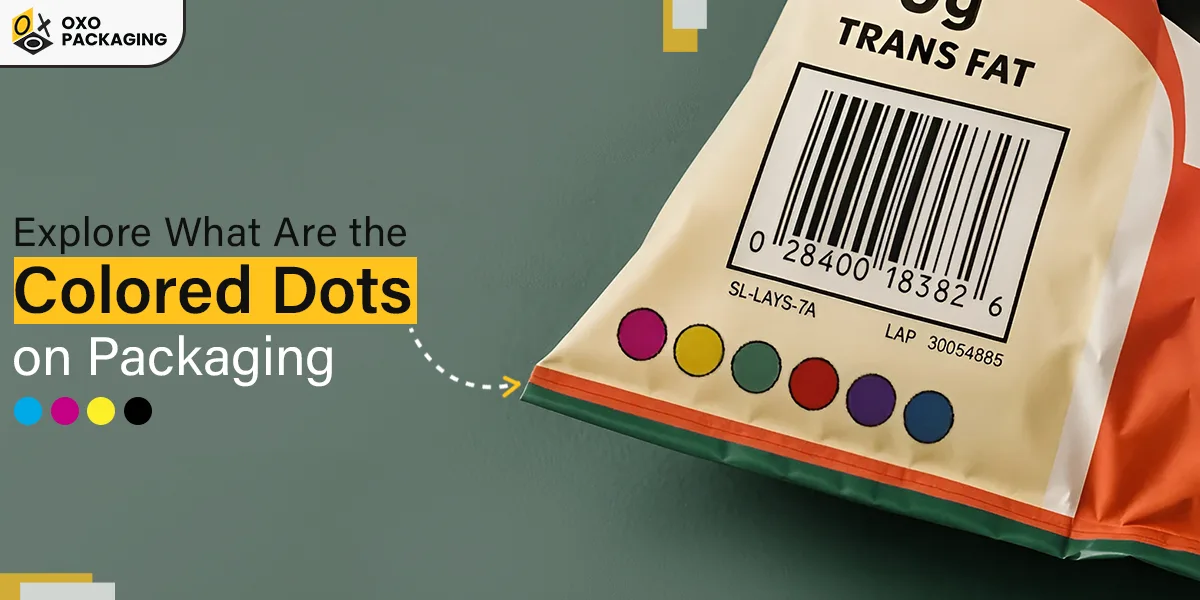

You are holding a bag of chips, a cereal box, or maybe a frozen pizza, and you spot small colored dots or circles printed somewhere near the edge of the packaging. They are usually red, blue, yellow, black, or green, sometimes just one color, other times a row of them.

Ever wondered what these colored dots are doing there? Despite the common myth that they represent ingredients, these little dots serve a very different and technical purpose in the world of packaging. Let’s unfold the mystery of what are colored dots on packaging!

What are the Colored Dots on Packaging?

Colored dots or circles are also known as printer’s color control patches or registration marks. Contrary to what many people believe, the colored dots have nothing to do with the product itself. They don’t tell you about allergens, preservatives, or expiration dates.

Instead, the colored packaging dots help manufacturers and printers control ink and color consistency during the printing process.

The Role of Primary Color Patches in Packaging Printing

To understand why these dots exist, it is useful to know how packaging is printed. Most modern packaging is produced using a CMYK color model, which is based on primary color patches. CMYK model stands for:

- Cyan

- Magenta

- Yellow

- Key (Black)

These four base inks can be combined in various proportions to produce virtually any color. Think of it like mixing paint, except done by high-speed industrial printers.

During the printing process, each ink is applied in separate layers. These layers must be perfectly aligned to produce clean and sharp images. Even a tiny misalignment can lead to color bleeding or blurry prints. That’s where the color dots come in.

What Do These Colored Dots Do?

Here is how these colored dots or patches help:

- Color Calibration: Each color dot shows how a specific ink is printing. If the cyan dot is too light or too dark, the technician knows there is an issue with the cyan ink feed.

- Ink Density Check: The dots help in assessing the ink density and saturation. If a dot appears faded, the press operator might adjust the ink levels.

- Print Alignment Verification: Because each color is printed in layers, the dots help confirm that all colors are perfectly aligned. This process is called “registration.” Misaligned dots may indicate a shift in printing plates.

- Troubleshooting Print Errors: If packaging comes off the press with incorrect color tones or blurry text, operators can check the dots to identify where the problem originated, whether with cyan, magenta, yellow, or black.

- Consistency Across Batches: Printers often run hundreds of thousands of units at once. Color dots help ensure the quality remains consistent from the first to the last package.

Are Colored Dots Always Circular?

Colored dots are not always circular. While circles are common, the marks can also appear as squares, rectangles, or bars. Their shape depends on the settings of the printer, the type of press used, and the design of the packaging itself.

In some cases, especially with rotogravure or flexographic printing, the control patches may appear as thin lines or color bars across one edge of the packaging material.

Do Different Products Have Different Color Codes?

Actually, the number and arrangement of colors on packaging depend on:

- The design complexity

- The colors used in the artwork

- Any spot colors or metallic inks included beyond CMYK

Some high-end packaging might use Pantone colors or additional inks like gold, silver, or neon shades. In those cases, the color patches might include those extra tones as well. But they still serve the same core purpose, which includes helping printers manage color accuracy and alignment.

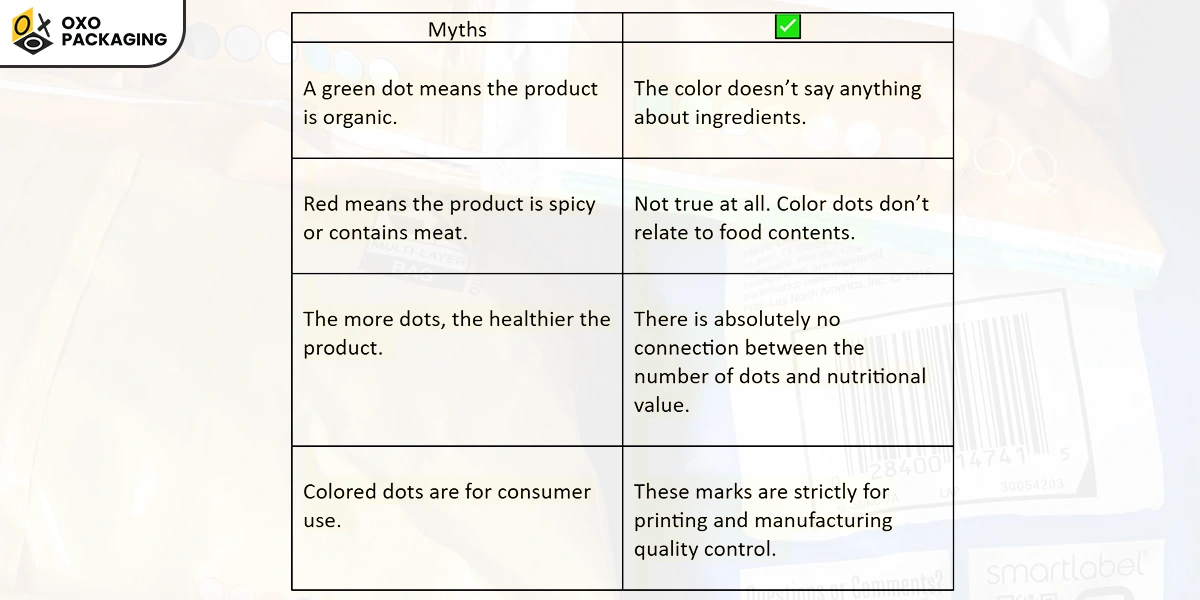

Common Myths About Colored Dots in Packaging

Let’s bust a few common myths about colored dots in packaging:

Other Print Marks You May Notice

Apart from colored dots, you might see other printing cues on your packaging:

- Crop Marks: Thin lines showing where the package should be cut.

- Registration Marks: Crosshairs used to align different layers of color.

- Bleed Area: Extra margin beyond the design area to ensure full coverage when cutting.

- Barcode and Scanner Blocks: Used to check scanner readability in retail.

All of these are part of the behind-the-scenes world of packaging production.

Why Should You Care?

While these dots might not directly impact your buying decisions, understanding what they are; can help you:

- Avoid misinformation when reading online rumors.

- Appreciate the complexity of modern packaging and printing.

- Identify print errors or packaging flaws, which could be helpful for quality inspectors or small business owners using printed labels.

If you run a business or are getting into product development, knowing about these print control marks can also help you better communicate with packaging suppliers or printers.

Final Words

The next time you spot those colorful dots on a cereal box or snack wrapper, you will know they are not some hidden ingredient code or secret health indicator. They are simply tools used by printers to ensure your package looks sharp, colorful, and high-quality.

These unsung heroes of the packaging world may not seem like much, but they play a huge role in delivering the perfect final product to your hands.

The next time you spot those colorful dots on a cereal box or snack wrapper, you’ll know they’re not some hidden ingredient code or secret health indicator. They’re simply tools used by printers to ensure your package looks sharp, colorful, and high-quality.

The colored circles on food packages are color calibration marks used by printers to ensure accurate and consistent color reproduction during the printing process.

Colored circles on packaging are primarily used by printers to ensure accurate color reproduction during the printing process.

Color dots mean color blocks or process control patches. They act as a reference for the printer, allowing them to check if the colors being used match the desired color scheme.