Explore What is Cardboard & Why Should Businesses Choose it?

Waqas Khan Pitafi 2025-08-15 07:38:57

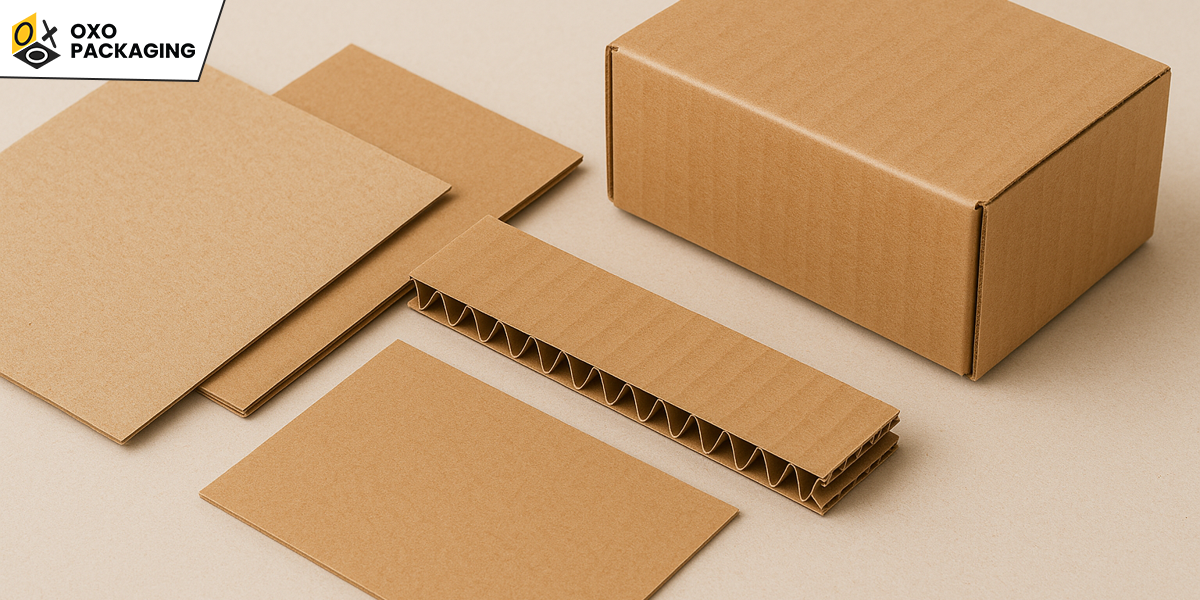

Cardboard is a common material, but it plays a crucial role in our daily lives. It is a versatile material used for various purposes. From packaging and shipping to customizing, cardboard serves best. This material is popular due to its lightweight yet sturdy nature.

Cardboard packaging is also eco-friendly. All these characteristics make cardboard an ideal packaging solution for businesses. If you are wondering whether cardboard is the right choice for your business, you should read this blog.

Learn what is cardboard and its benefits for businesses serving in versatile industries.

What is Cardboard?

The term “cardboard” is a broad term used for heavy paper-based products. Cardboard is made from multiple layers of paper. Natural cardboard appears grey to light brown, but its color varies depending on dyes, pigments, printing, and coatings.

The primary purpose of cardboard is to provide superior strength to inside-packed contents. Despite their sturdiness, cardboard boxes are portable enough to carry due to their lightweight nature.

What is Cardboard Made of?

Cardboard originates from either paper pulp or reused fibers. Paper pulp breaks down into bland sheets after processing. Afterward, it transforms into cardboard products such as corrugated cardboard and paperboard.

Compared to paperboard, corrugated cardboard is more durable. Because corrugated cardboard has middle fluting layers embedded between the paperboard. This process is also known as “corrugation”. You can craft in various thicknesses, colors, or textures to meet your specific packaging needs.

2 Main Types of Cardboard

There are two main types of cardboard: paperboard and corrugated fiberboard. The main difference between both lies in their thickness and layering. Corrugated cardboard is a multiple-walled layering. It is thicker as well as sturdier compared to paperboard. Let’s discuss each in detail:

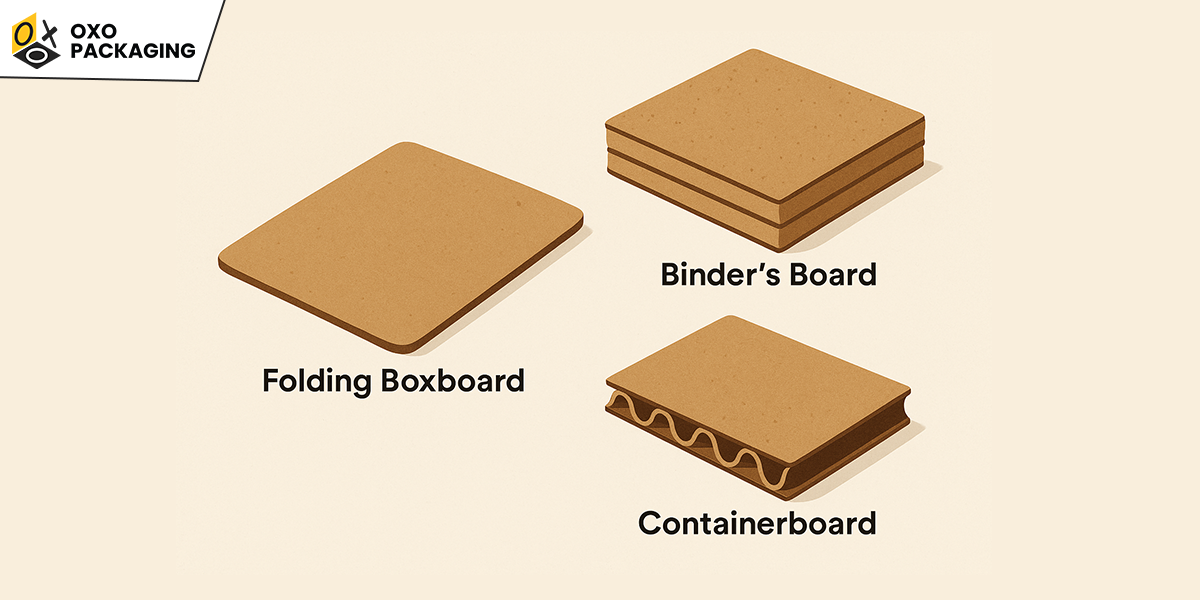

Paperboard

Paperboard is a paper-based material. It usually has more than ten mils, e.g., 0.010 inches or 0.25 millimeters thick. This material is mostly used for making folding cartons and set-up boxes. The composition of paperboard includes:

- Folding boxboard

- Binder’s board

- Containerboard

Corrugated Fiberboard

Corrugated fiberboard is also a paper-based material. It is basically a combination of paperboards. The layering of paperboards is often two flat liners and one inner fluted corrugated medium. Corrugated boxes are usually made from corrugated fiberboard.

These boxes are excellent for shipping or storing items. Many artists use this type of cardboard as original material for sculpting. Heavy-duty corrugated fiberboard is resistant to water, unlike regular corrugated fiberboard.

Manufacturing Process of Cardboard

The production process of cardboard involves multiple steps. It converts raw materials into the final cardboard product. Have a look at the step-by-step guide:

Pulping: The first step in making cardboard is pulping. The process of pulping involves breaking down raw materials to form a fibrous pulp. Pulping can be achieved through two methods: mechanical and chemical.

Mechanical pulping breaks down wood into fibers. But chemical pulping uses chemicals to disintegrate wood into fibers. If you want eco-friendly sourcing, then opt for mechanical pulping, which eliminates the use of chemicals.

Cleaning: After the pulping process, remove residual impurities from raw materials. The cleaning process ensures a high level of purity by removing bark, dirt, or ink residues. It results in laying the foundation for the production of high-quality cardboard.

Bleaching: Go for bleaching to gain a consistent and uniform color. As original color of wood pulp is brown. White color is acquired by bleaching the pulp, which removes any residual tints from source materials.

Forming: Utilize a machine named “Fourdrinier machine” to transform pulp into flat sheets. As a result, a layer of pulp forms when pulp is poured on a flat surface for draining.

Pressing: Once pulp sheets are formed, they go through a pressing process. In turn, a smooth surface is created by pressing these sheets between large presser rollers.

Corrugation: Put flat sheets of cardboard under the “Corrugated machine.” Doing so enhances strength and durability. The process of corrugation gives a unique pattern by putting wavy flutes between two flutes.

Cutting and Shaping: In the last step, you can make various things from cardboard sheets. Use the cutting and shaping method to create items, like boxes or folding cartons.

Learn About Grades of Cardboard

Diverse grades of cardboard are available. Categorize these grades based on the percentage of recycled fiber they contain. All these grades are recyclable. Let’s dive into these grades:

- Kraft: Made from pure fibers that have never been recycled before.

Chip: Comprised of 100% waste-based liners. - Bleached White: Contains a bleached Kraft liner that is made from pristine fibers.

- White Top: Has a white coated liner that is made from recycled fibers.

Mottled Kraft: Uses a combination of virgin and recycled fibers to achieve mottled Kraft.

Tidbit: Always keep in mind that contaminated or wax-coated cardboard by food or other substances can’t be recycled.

Why Should Businesses Use Cardboard Packaging?

The perfect blend of durability, customizability, versatility, and recyclability makes cardboard packaging ideal for retail to industrial businesses. Consider these benefits to take advantage of cardboard:

- Packaging and Shipping: Cardboard boxes are suitable for packaging and shipping items due to their robust construction, lightweight nature, and budget-friendly cost. These boxes also provide high-level protection to fragile items. Plus, they are easy to stack and transport.

- Storage: Cardboard becomes an effective tool for organizing and storing items, especially for retail businesses. Boxes made from cardboard can be customized in multiple sizes and designs to meet different storage needs.

- Customized Packaging: Cardboard is a preferred material due to its versatile customizability in the realm of packaging. It is flexible in cutting, folding, and printing. So, cardboard becomes suitable for various artistic projects.

- Budget-Friendly Option: For every business, production is a great concern. Cardboard meets the effective cost expectations of businesses. Moreover, its lightweight also reduces shipping costs.

- Eco-Friendly Material: Cardboard is a superbly environmentally friendly material. It is recyclable and biodegradable. In today's world, modern consumers are becoming more eco-conscious than ever. Hence, opting for cardboard can attract eco-aware customers and boost ROI for your business.

Conclusion

Cardboard has knocked out all other packaging solutions due to its exceptional properties. Hence, it has become an unavoidable packaging material for businesses. To boost customer engagement and sales, smart businesses invest in custom cardboard boxes. You can also order these boxes designed with premium quality by partnering with OXO Packaging.

Cardboard is an eco-friendly material. It is made from cellulose fiber, such as wood pulp, like paper, but usually thicker.

Cardboard is an environmentally friendly material. It is biodegradable and recyclable in nature. Made from recycled paper pulp, cardboard becomes 100% recycled.

Cardboard is made of paper fibers. Fibers are derived from wood pulp. This pulp is processed and transformed into sheets known as “corrugation”.

There are three types of corrugated cardboard based on the middle layer fluting. These types are single-wall, double-wall, and triple-wall.