Wondering about What PMS Color is? Read on to Find More

Are you sick of your designs using different colors? Do you want to be sure that your brand's colors are consistently faithful to your vision and accurate? PMS is the only place to look!

Each color in PMS has a unique number that makes communicating and duplicating certain colors easy. Printing services and designers may get exact color matching with this technique, regardless of the media or printing process.

This blog post will delve deeper into the realm of PMS colors and explore their benefits and applications in the design and printing sectors.

What is the Pantone Matching System?

What does PMS color stand for, is an often asked question.PMS color, also known as Pantone Matching method color, is a standardized color reproduction method used by printers and designers. Ever since it was developed in the 1960s by the Pantone Corporation, it has remained the industry standard. To provide color accuracy that is consistent across a variety of materials, such as plastics, textiles, and printed materials, PMS colors are excellent to use.

History of Pantone System

The roots of PMS color lie in Pantone which was a commercial printing company started in 1950. Lawrence Herbert, one of the young employees of Pantone found it difficult to match the colors of the design for printing. Matching the exact shades when printers print the graphics used to be challenging.

In 1963, Lawrence designed a way to give a numeric value to each shade of color. That’s how the Pantone matching system was invented. With the help of this system, we can now match the colors of the graphics designed, and print the exact shades of colors.

How Does PMS Color Work?

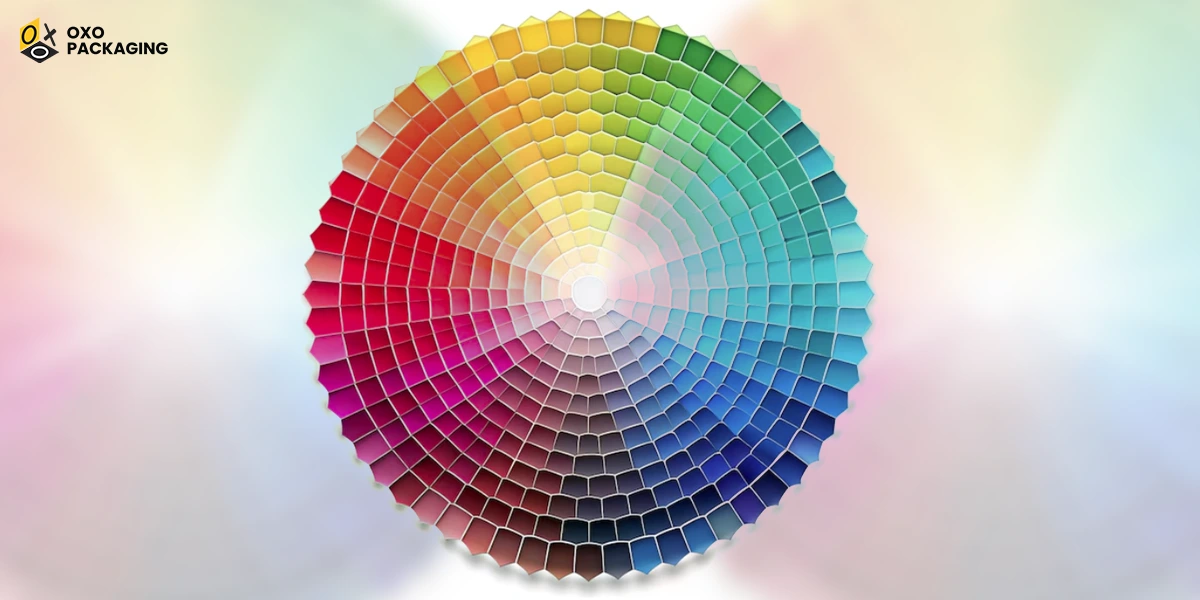

A standardized color scheme used in many industries, such as printing, graphics, and design, is called the (PMS) Matching Color System. But, a question arises here: how does this system work proficiently to give high-quality color results? Here is a brief guide to the Pantone color-matching process:

- PMS colors are used to ensure accurate and uniform color reproduction across different materials and printing techniques.

- The PMS guidebook specifies the precise ratios at which base colors must be mixed to create each PMS color.

- This guidebook makes it simple for designers and printers to communicate and replicate certain colors by including samples of over a thousand hues, each uniquely recognized by a number.

- Due to the narrow color spectrum, the PMS method cannot reproduce every hue. However, it offers a wide range of colors that are popular and commonly used in the industry.

- Designers can mix exact amounts of basic colors to generate custom PMS colors in addition to the conventional PMS colors. This allows them to acquire the shade they want.

- Businesses and organizations frequently utilize PMS colors to create and uphold consistent branding across a range of marketing materials and goods.

- Understanding how PMS color works helps designers and printers achieve accurate and consistent color results, ensuring the desired look and brand identity.

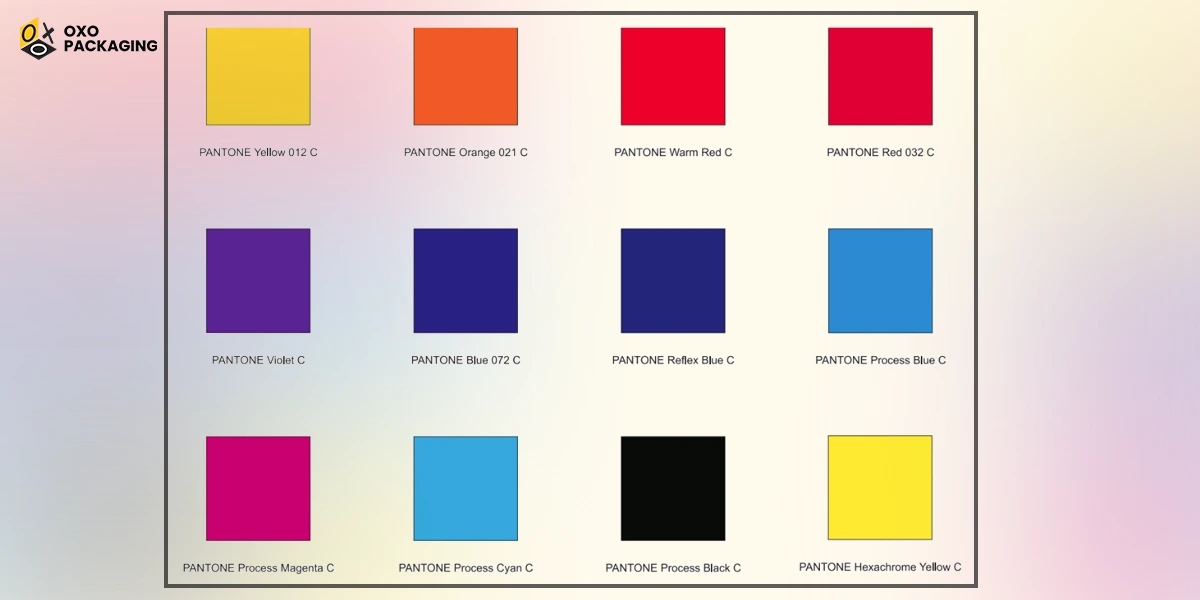

PMS Color Palettes

PMS comes with different color palettes allowing you to choose from a wide range of color selections for accurate and captivating results. The most common PMS color palettes include:

- Goe palette

- Textile palette

- Process palette

- Pantone solid palette

Thousands of colors and shades are included in these palettes. You can choose one that resonates with your brand and meets your requirements as well. Among these palettes, the most commonly used and excellent one is Pantone solid.

PMS Colors Meaning in Design

Pantone Matching System (PMS) colors are a collection of standard colors used in the printing and design industries. Every PMS color denotes a distinct shade and has a designation, such as PMS 200.

Due to their ability to maintain accuracy and uniformity across a variety of media, these colors are frequently utilized in branding and marketing materials.

By utilizing the PMS color system, designers may efficiently convey their intended color to printers, guaranteeing the correct result for the finished product.

Benefits of Using PMS Color

From designing to printing, the importance of enchanting color schemes is undeniable. The selection of the right color theme helps designers make persuasive graphics that convey messages to their target audience.

And, PMS is one of the most efficient color-matching systems providing you with accurate and quality results. Explore the benefits of using PMS (Pantone Matching System), and why it is essential for your brand:

Accuracy and Stability

The ability to reproduce color consistently and accurately is one of PMS color's biggest benefits. Because PMS colors are carefully blended and matched, you can be sure that the color you select will always be the color you receive.

For brands that substantially rely on their visual identity to convey their message and elicit particular emotions, this is extremely important. You can be sure that your brand colors will be the same in all of your marketing materials—print and digital—when you use PMS color.

Brand Identity

In order to create and maintain a powerful brand identity, colors are essential. With PMS colors, you may design a distinctive color scheme that expresses the character and principles of your company. You can specify the primary and secondary colors of your brand and make sure they are consistently replicated by utilizing PMS color.

In the end, this consistency strengthens brand recall and recognition by assisting customers in identifying and associating particular colors with your business.

Precise Color Representation

PMS colors are essential for brands and companies with well-established color schemes since they are created using certain ink combinations to produce exact tones. PMS colors are pre-mixed for more precise color representation than CMYK or RGB color modes, particularly for colors outside of those color spaces. For tasks needing color precision, such as printing logos or brand collateral, PMS colors are thus recommended.

Easy Color Communication

PMS colors are uniquely identified by numbers, which makes color communication between design and printing processes simple. To keep everyone in the loop, these statistics act as a common language for clients, printers, and designers.

Using PMS color codes simplifies the procedure, lowers the possibility of color variations, and promotes an effective workflow, all of which help to avoid expensive printing errors.

Matchless Color Range

The PMS system provides designers with an exceptional range of colors, allowing them to find the perfect & precise shade to match their creative vision or brand requirements. With multiple standardized colors, designers can explore new possibilities and push the boundaries of their creativity, knowing they can achieve precise color reproduction with PMS inks, ensuring a wide range of colors to suit any aesthetic.

Improved Print Quality

PMS colors are commonly used in spot color printing, which produces vivid, bright, and crisp prints with uniform color accuracy and intensity. This method differs from process printing, which blends CMYK inks. PMS colors provide clear, realistic colors that accurately capture the designer's vision, making them suitable for promotional items, packaging, and marketing materials. This technique can enhance the impact and quality of printed items.

Optimal Production Process

Printers can easily match given colors without any modifications or conversions thanks to PMS colors, which are pre-mixed and standardized. This reduces mistakes and saves time by streamlining the production process.

In addition to maximizing ink use and decreasing waste, PMS colors help save costs and promote environmental sustainability. PMS colors increase productivity by streamlining the printing process and guaranteeing consistent output, which helps to improve production workflow efficiency.

PMS Color in Different Industries

- Printing and Graphic Design: PMS colors are standardized color codes used in the printing and graphic design industry to ensure consistency across different print materials. They enable designers to accurately communicate their color choices to printers, ensuring the intended color appears in the final product, particularly important for logos and brand identity materials.

- Fashion and Textiles: PMS colors are crucial in the fashion and textiles industry for creating color palettes for clothing, fabrics, and accessories. They maintain consistency across different materials, ensuring garments and accessories match the intended color scheme, especially important for fashion brands and designers seeking a distinct color identity.

- Packaging and Product Design: In order to create visually appealing and consistent designs that complement the brand's identity and have a strong visual impact, PMS colors are essential in the branded product packaging and product design business. Additionally, they retain uniformity while working with various media and printing processes, such as flexography or offset printing.

Challenges and Considerations with PMS Color

The challenges and considerations highlighted emphasize the importance of careful planning and communication when working with PMS colors to achieve the desired color outcome. Read below!

- Color Matching: Achieving an exact color match can be challenging with PMS (Pantone Matching System) colors. Different printing processes and materials can result in slight variations in color, making it difficult to ensure consistency across different products or projects.

- Limited Color Mixing: Although the PMS color range is exceptional in quality, yet has limited mixing capabilities as compared to other color systems like CMYK or RGB. This means that certain shades or hues may not be available in the PMS color library, making it necessary to compromise or find alternative color options.

- Cost: Working with PMS colors can be more expensive compared to using standard process colors. PMS inks need to be mixed and prepared separately, increasing production costs. Additionally, PMS color guides and licenses can be costly, especially for businesses that require frequent color matching.

- Color Reproduction: PMS colors may not reproduce accurately on all printing materials or surfaces. Factors such as the type of paper or substrate, printing method, and color calibration can affect the final appearance of the PMS color, making it important to consider these variables when using PMS colors.

- Limited Accessibility: PMS colors are not as widely supported as other color systems. Some digital platforms or software may not have built-in support for PMS colors, requiring manual conversion or approximation of PMS colors using alternative color systems.

Lastly, for projects needing exact and correct color, a trustworthy printing provider is essential. They can precisely replicate PMS colors thanks to their technology and experience, guaranteeing the required outcomes.

They can deliver your project the greatest outcomes since they have a vast selection of color alternatives and a solid grasp of color management.

Two Different Pantone Matching Systems

There are two different systems for Pantone matching, which helps brands to boost their design game. One Pantone color system is specified for products only and the other one is specified for products’ packaging. Both have different color schemes and pallets that can easily align with your products and their packaging.PMS has nearly 5,000 Pantone colors in total.

Both product and packaging design different systems are made to understand Panton’s market-relevant colors that are used by industries for products and packaging. The difference between Panton colors for the product have shades like black, white, or neutral color schemes. On the other hand, the color shades for the packaging have shades that help your product packaging stand out on the retail shelves.

Some colors look different on different materials when applied. This why Pantone has divided the colors into two systems to help product creators and packaging manufacturers to use the right color scheme without wasting their time on experimenting.

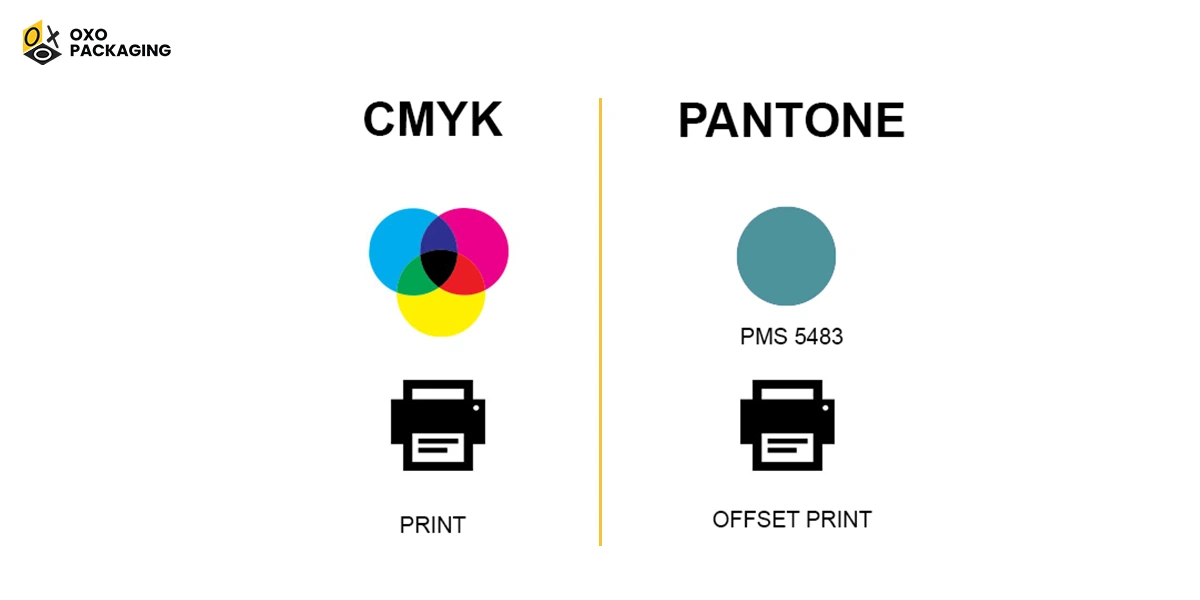

Can PMS be Converted to CMYK?

Converting PMS to CMYK can be done but it could be challenging. Because many of Pantone colors to CMYK do not come out as good as they look without getting printed on the materials. You can use a set of Pantone colors to reproduce them using CMYK for the right application on the product or its packaging. In short, it is possible to convert PMS to CMYK with more expertise and the right techniques while getting them printed on the surfaces. Use Pantone’s conversion guides to find the best possible matches.

Can CMYK be Converted to PMS?

You can convert CMYK to PMS using graphic design software like Adobe Photoshop or Illustrator. Professional product and packaging designers know the techniques to convert CMYK to PMS.However, most retail brands use CMYK rather than PMS for their product and packaging design because Pantone’s colors are expensive.

PMS Vs CMYK: Which One is Better?

CMYK color mixing and matching system comprises four hues: cyan, magenta, yellow, and black (key). These colors are mostly printed individually and layered after printing. CMYK color scheme has significant variations and may not give you accurate and consistent output of color printing.

On the other hand, PMS has a collection of a wide range of colors having no specific color model. It allows you to print a more extensive range of hues as compared to CMYK. Also, the color consistency is remarkable making it a standard for various designers and printing services across the globe.

PMS Vs RGB

Unlike PMS, the RGB system is used for digital use. The RGB stands for Red, Green, and Blue colors. It is an additive color model because it is based on light. Rather than being blended in ink, the three colors are mixed with the blending of light to get new colors for digital designs. The designs on websites, social media apps, and other digital platforms are a blend of RGB.

Experience Perfect Color Accuracy With OXO Packaging

Are you trying to find trustworthy and effective printing services? OXO Packaging is the only place to look! We are among the reputable packaging companies in the US offering matchless services at a wholesale price.

We offer PMS color matching to ensure the correct reflection of your desired colors in printed products. Also, you can avail of free design support from us to customize your packaging, labels, stickers, and more. Contact us to get the right packaging solutions your business needs!

Final Words!

PMS color is one of the most efficient and reliable color mixing and matching systems. It comes with endless color options allowing you to choose an exceptional color palette for professional and top-notch designing and printing. This blog has discussed everything you need to know about PMS colors.

If you have any queries related to this remarkable Pantone matching system, feel free to ask us. You can also benefit from our top-tier printing services for your packaging, labels, stockers, and more.

You can figure out the PMS colors of your logo or anything else with the help of online tools. However, if all of this feels like a daunting task, let our design team assist you in finding the perfect color match for you.

PMS is a color system of premixed inks used in printing to ensure accuracy and brilliancy in the results. From fashion to manufacturing, this system is widely used because of its applications and results.

No, HEX is used for digital use, whereas PMS is used for printing on surfaces such as flyers, brochures, packaging bags, and packaging boxes.

The Pantone Matching System is a standardized color library that gives each color a unique number, making color printing consistent across all materials and printers.

No. Screens use RGB, so the color only becomes accurate when printed according to PMS specifications.