How to Measure Box Dimension Before Making Packaging Boxes and Shipping Them

Making a product and measuring its dimensions is the first step. Hence, you can pack your products in mailer boxes for shipping or other types of packaging boxes. These boxes are ideal for protecting your products during transit and ensuring a professional presentation. Once packaged, you can sell your products in retail stores or through e-commerce websites. First, let me show you how to measure your products to make packaging boxes. Then you can read how to measure the box dimensions for shipping.

Tool:

You only need a measuring tape or a ruler scale.

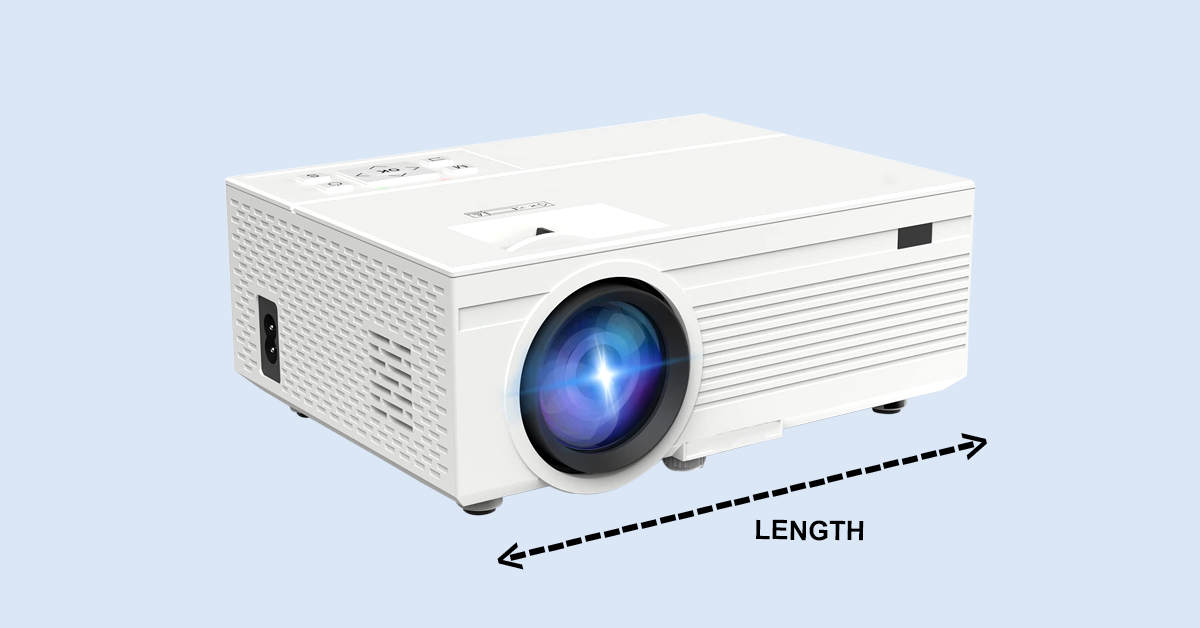

Step 1:

Measure the longest side of the product by lying it on a smooth surface. It is the length.

Step 2:

Now rotate the product and measure its wider side. Width is also known as all three dimensions of the product.

Step 3:

Thirdly, measure the product from top to bottom. This is called the height of the product.

The Importance of Inside Dimensions

If you have contacted a packaging company to make your boxes, then first, always measure the inner dimensions of your required “packaging box” because this is how you will know how to place your goods in the product boxes eventually. Knowing about the inside dimensions of the packaging boxes is very important.

Many retailers buy bigger product boxes for their commodities. They randomly buy Kraft boxes or plain boxes from Amazon. Because those boxes are relatively low-priced, they think they are buying cheap boxes. But there are a lot of possibilities that your product will need to fit in the box adequately. As a result, they have to buy additional packaging inserts to fit their products snugly.

So, it is better to know how to measure a box. Then measure the inner box dimensions. And always buy custom packaging boxes. Personalization allows you to make the packaging box according to your product dimensions.

Hence, you will save a handsome amount. Moreover, when you go for custom printed boxes, you can get them in your required sturdiness, as printed boxes come with different materials. Cardboard boxes, Kraft boxes, Rigid boxes, and Corrugated boxes are famous packaging boxes. They all have different material thicknesses.

So, when you buy a custom box, you get the box dimension of your requirement. Indeed, you get all packaging solutions of your own choice. You just have to measure the dimensions of your product. And then you get the best and most useful packaging boxes.

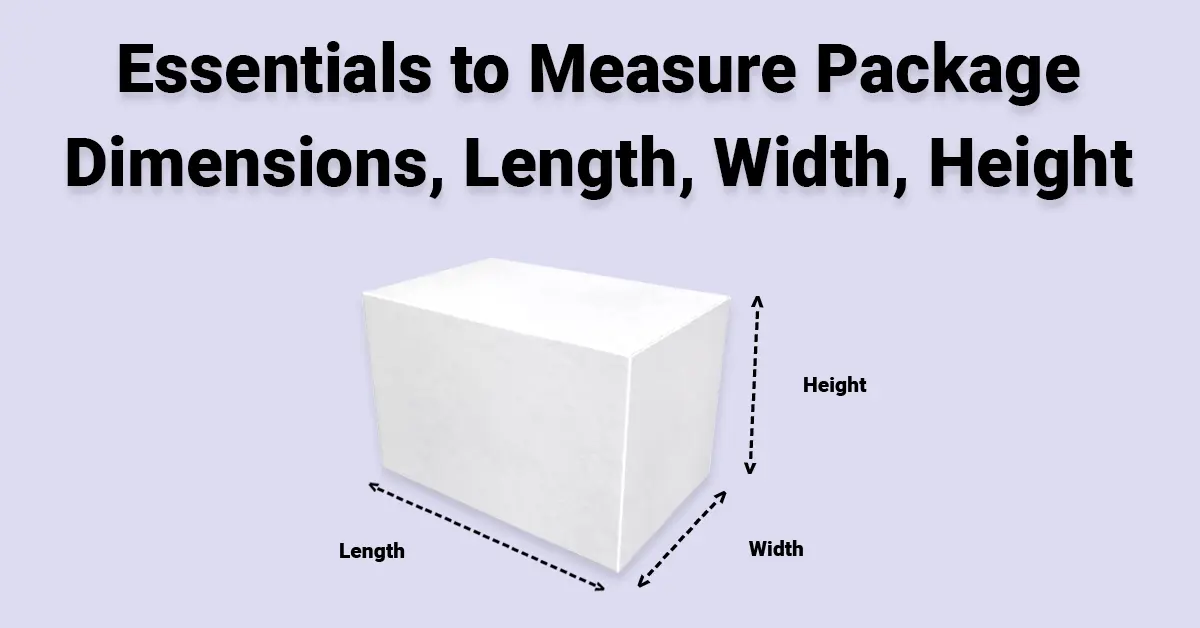

First, remember the basic dimensions formula is length, width, and height. It is also known as LxWxH. So, first, you will measure the length. Then you will measure the width. And later, you will take the dimensions of height. This is how you send product dimensions to your packaging company.

Many times, retailers provide product images to their vendors too. This is how it becomes easy for packaging designers to make product designs. Product designers devise the most suitable styles of packaging boxes after getting accurate dimensions. For instance, they can give you options like Mailer Boxes, pyramid-style boxes, straight-tuck end boxes, reverse-tuck end boxes, etc.

Hence, product dimensions help you get the best packaging boxes. Before knowing how to measure a box, let’s learn a few steps of product measurement that you must follow.

Must Follow Essentials to Measure Package Dimensions, Length, Width, Height

To know how to measure package dimensions, understand the following method. For instance, if your product has the below dimensions:

7” x 5” x 2”

LxWxH (Length, Width, Height)

Now you cannot make the box of exact dimensions, 7” x 5” x 2”. You must give a little bit of extra space inside the packaging box. This is how you can snugly place the product in the packaging box.

The exact dimensions are not suitable for the inner side of the packaging box. You always have to extend the inner spacing of the packaging box. Hence, the inside dimensions of your packaging box will be as follows.

7”.1cm x 5”.1cm x 2”.1cm

You should extend one-centimeter spacing more than the exact size of your product. The increased one-centimeter spacing, more than the product size, will give you the required gap to fit in the product properly. Because this is how your packaging box will remain safe; moreover, you will not have to forcefully insert the product into the packaging box. And a bigger inside dimension of the packaging box is important for easily picking out the product from the box.

Why Do You Need Bigger Inside Dimensions of the Packaging Boxes?

A bit of vast space inside the packaging boxes will give more comfort to your customers. This is how your customers will easily grab the products. You should also give extra spacing to the closing tuck of the packaging boxes. Hence, you can easily close the lids of the packaging boxes. And this is how you give more room and space to your customers to insert their fingers in the packaging boxes and pull out the products easily. So, extra space is beneficial for product packaging and user experience.

Sometimes, you must make bigger inside dimensions of your packaging boxes as many products demand more spacing inside the boxes.

For instance, if you have to pack perfume, cell phones, or any high-end product, they need bigger inside dimensions because you have to lay inserts in the packaging boxes. Bigger interior dimensions of the packaging boxes are also required to produce boxes. Because packaging companies make retail boxes from a single piece of paperboard, these materials can be cardboard, Kraft, rigid, and corrugated. Now let me show you how to measure a box as follows:

How Do Packaging Companies Measure the Box Dimensions?

This part of the blog will be helpful for you to know how to calculate dimension of a box. Packaging companies set the size of the packaging box; they use a single sheet of paperboard. This is also called an “open-size sheet.” Later, by following the inner dimensions of the packaging box, they devise a style for the packaging box.

A die-cut machine cuts the paperboard according to your box's dimensions. The die-cut machine brings the folding creasing to the box. This is how they fold cardboard and different paperboards.

After folding the creasing, paper stocks get the shapes of packaging boxes. Once the paperboard gets the shape of a packaging box, now inside dimensions will be permanently fixed. Then you can only measure the packaging box from the outside. Now let me show how to calculate dimension of a box from the outside.

How to Measure a Box for Shipping?

Now I will show you how to calculate the box for shipping. For this, first, you need to know how to measure a box from the outside. Sometimes you come across the small box dimension, and sometimes you have to measure the large box dimension.

Remember, the following method is for rectangular boxes.

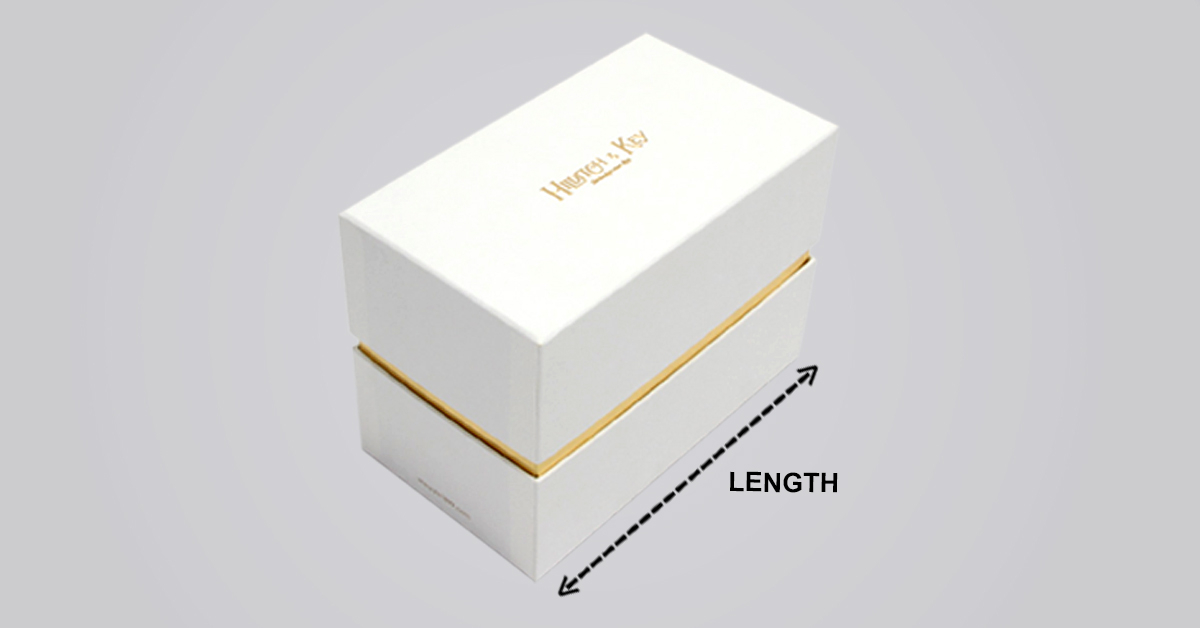

Step 1:

Measure the length. It is the longest size of the box. When you look at a packaging box, it looks like a cube. You always have to measure its only three sides.

These three sides of a packaging box get repeated. It does not matter from which side you measure the box. Pick any of the longest sides of the product box, and it will be the length of the box.

Step 2:

After length, rotate the measuring tape up to 90 degrees. This is how you can measure the width. This side is also known as breadth. Some of our American folks also call this box-side the depth. If you buy rectangular packaging boxes, you will need to measure the three sides of the packaging boxes. If you have shopped square boxes, you don’t need to measure all sides of packaging boxes specifically because square boxes have the same dimensions on each side.

Hence, you don’t need to measure all three sides of this packaging box. Just Measure one side of the box. That’s it. Hence, you can take the box measurements for shipping.

Step 3:

Now, vertically measure the box. This is the height of the packaging box. First, you should tightly tuck in the opening flaps of the packaging box. Similarly, close the lower flaps. Then measure the box dimension. This is how you will get the exact measurements.

How to measure different shapes of Boxes

Packaging boxes have different shapes. Packaging companies make boxes in many styles and shapes. So, it is necessary to learn about measuring other shapes of boxes too. First, let me show you how to measure cylinder boxes.

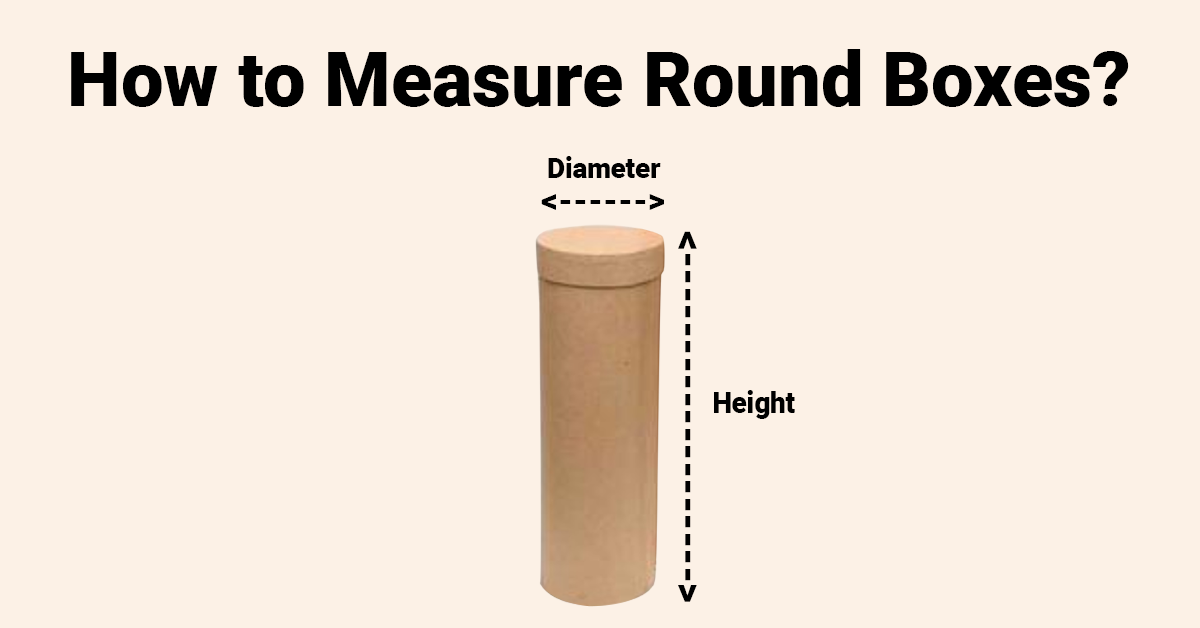

How to Measure Round Boxes?

Packaging companies make boxes of spherical shapes. Retailers know these boxes by the names of cylinder boxes, tube boxes, or round boxes. So, the following dimensions are for the tube, round/circular boxes.

The round box has a round-shaped top and bottom. Its lid and bottom are always of the same size. So, while measuring round boxes, you only need to measure the top or bottom once. So, the formula to measure round boxes is as follows.

DxH

It means Dimension x Height.

Dimension is a straight line across the lid or bottom of the round box. So, the example measurement of your round box can be 5” x 11”

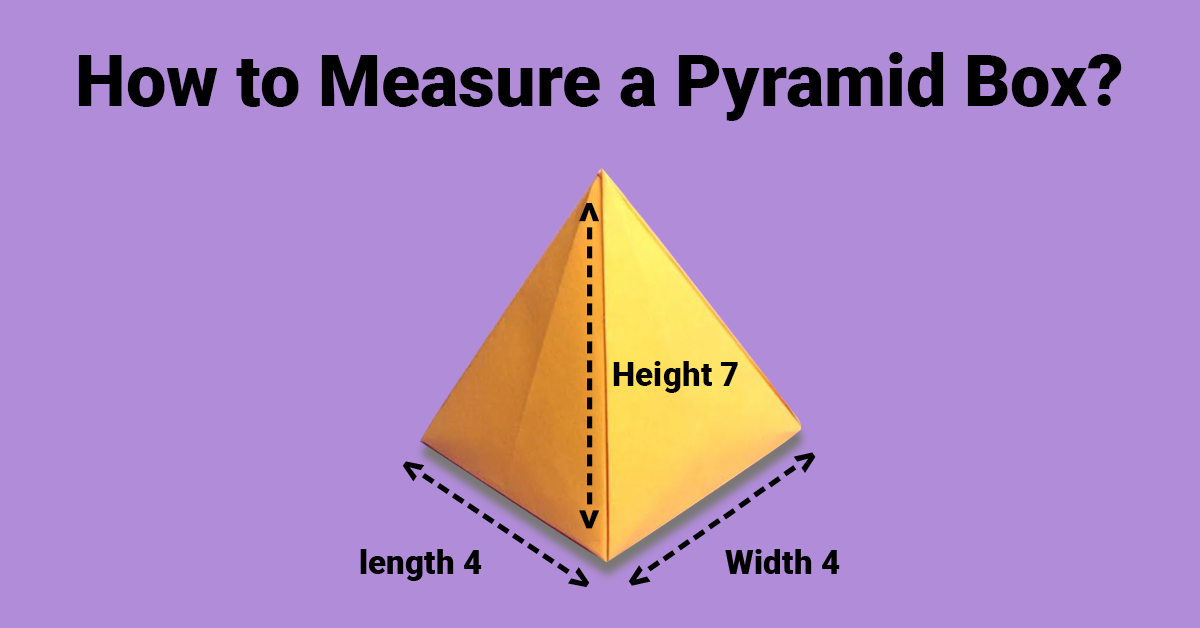

How to Measure a Pyramid Box?

Retailers know these boxes by the name of pyramid boxes or cone boxes. Pyramid boxes have a bottom; its three corners connect upwards in the center. Retailers use this style to make pizza slice boxes or bakery boxes.

Now I am showing you how to measure a three-cornered box. The following formula is best to measure pyramid boxes.

LxWxH

3

Multiply the total area (Length x Width x Height) of the bottom of the pyramid box by its height, then divide by 3.

For instance, your pyramid packaging box has the following dimensions.

4” x 4” x 7”

LxWxH

By this, the total area of your pyramid box is 112 inches. Now divide it by 3. The total volume of your pyramid box is 37.3”.

How Do Cargo Companies Charge the Freight?

Couriers charge the freight by two methods when you send your products by air. First, they calculate the total weight of your Product Boxes on a scale. If the product boxes are heavy, they will charge based on weight.

Because there are many types of custom product boxes, sometimes retailers make products in tiny sizes. Then they pack them in small packaging boxes. But those products may have immense weight. So, in this case, air carriers do not prefer the box size. Instead, they follow the “weight method.”

Usually, Air carriers circulate air freight charges every month. They make price lists based on per kilogram. Most of the carriers start per kilogram fee from the category of below ten kilograms. Then they increase the freight according to the weight limits.

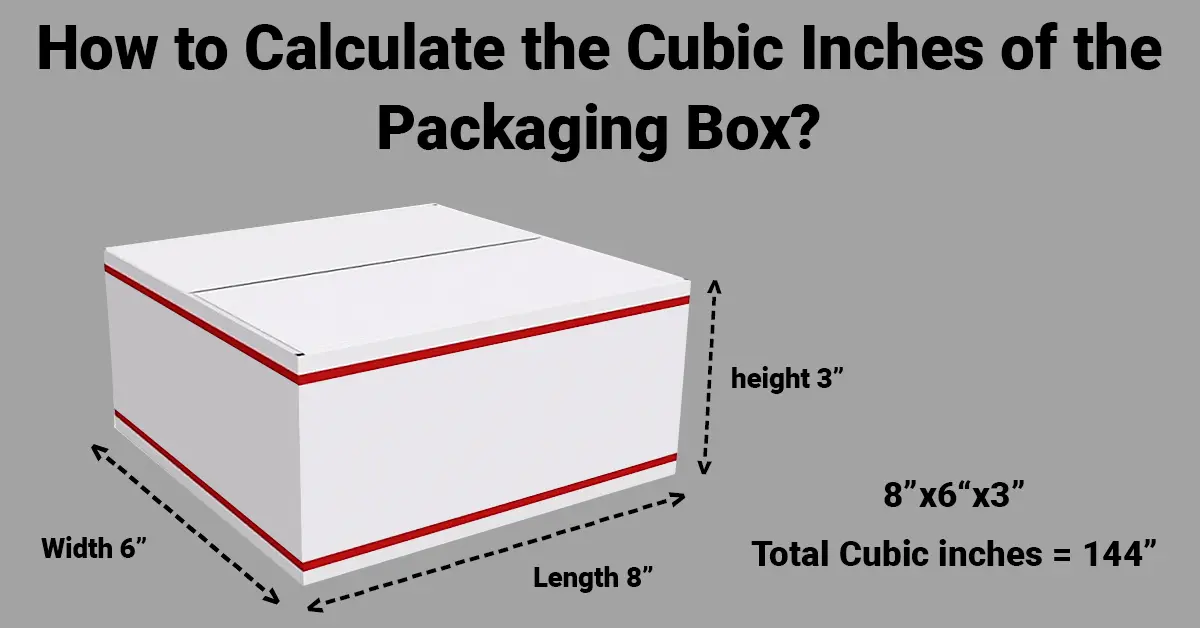

How to Calculate the Cubic Size of the Packaging Box?

The second option for Couriers is to measure the dimensions of your product boxes. They measure the total cubic size of your packaging boxes. They use the same three-sided formula to calculate the exact size of the boxes. As mentioned above, this is a famous measurement formula Length X Width X Height (lxwxh).

For instance, your box dimensions are as follows:

8” X 6” X 3”

LxWxH

To get the cubic size of the box, you should multiply all three dimensions of the packaging box as below.

8” X 6” X 3” = 144”

Hence, after multiplying all three dimensions, length, width, and height, you can get the total cubic size of your packaging box. So, assuming the length of your box is eight inches, the width is six inches, and the height is three inches, then the total cubic size will be one hundred and forty-four inches.

What Types of Box Dimensions do Carriers Prefer?

Once the Couriers get the exact cubic size of the box, they follow the “higher value formula.” Let me elaborate more; now, carriers will apply the formula by first looking at the net weight. If the actual weight of the packaging box is more than the dimensional weight, then they will only charge the net weight. And they will ignore the size of the product boxes.

But if the dimensional weight is higher, they will overlook the net weight. Now the carriers will only follow the box dimensions, and they will see how much area of the carrier your packaging boxes cover. Shipping companies always follow the formulas of “weight” and “volume.”

Because they say there can be many product boxes with large sizes and minimum weight. So, they cannot only follow the “weight” criteria to apply the freight charges. Eventually, they have to follow the volumetric weight of the packaging box. This is where they take help from the box dimension.

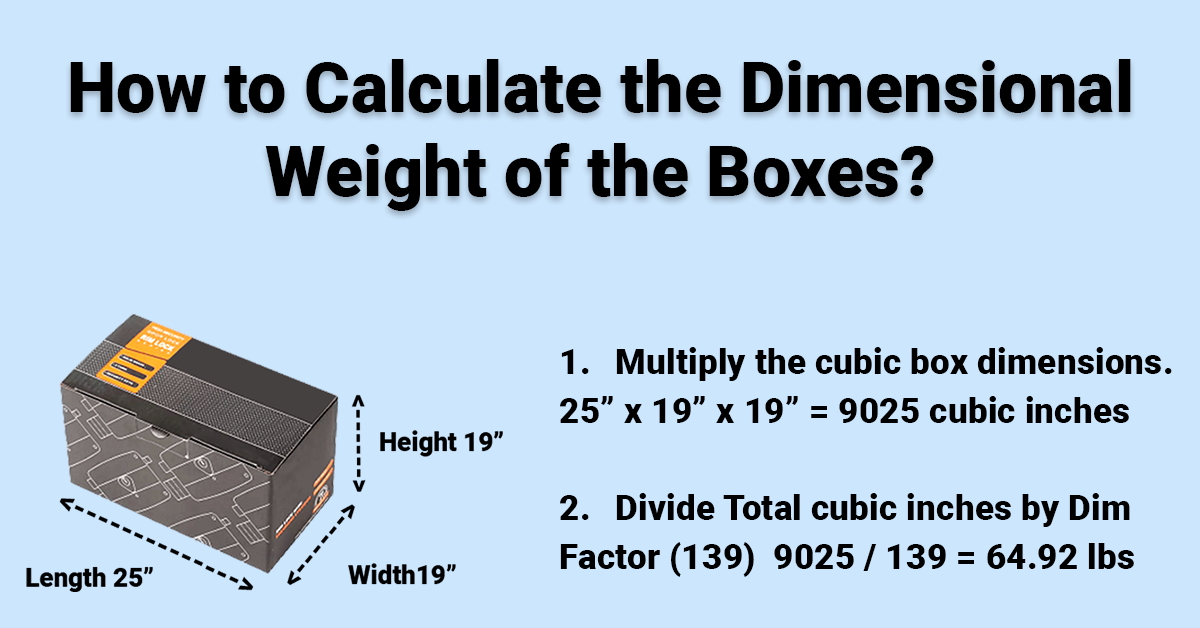

How to Calculate the Dimensional Weight of the Boxes?

Retailers also know dimensional weight as “Dim Weight.” This is an alternating form of the weight devised by the carriers. Some people also call it “theoretical dim weight.” Always remember dim weight is not the actual weight. It is only a conceptual weight that shipping companies devise after measuring the box dimension.

Now, I am quoting the examples of two courier companies. These companies are UPS and FedEx. Each company has its own Dimensional (DIM) factors. I am quoting the DIM divisors of these companies only to show you the formula of dimensional weight. The existing DIM formulas of these two courier companies are as below.

UPS: 166 (Retail Pricing)

FedEx: 139

DHL also provides you with a DIM factor of 139. Let’s look at an example of getting the dimensional weight.

For instance, if the weight of your packaging box is 40 lbs and you are shipping it through FedEx. Furthermore, your packaging box measures 25” x 19” x 19”. Then you will have to follow the below steps.

Multiply the cubic box dimensions.

25” x 19” x 19” = 9025 cubic inches

Divide Total cubic inches by Dim Factor (139)

9025 / 139 = 64.92 lbs

Hence, the dimensional weight of your packaging box is 64.9 lbs which is higher than the net weight of 40 lbs. The Courier company will likely round it up. So, they will charge the freight of 63 lbs.

Note: this is a dimensional factor formula devised by the courier company. Whenever you have to find fresh rates, contact the courier company's sales department.

Why Do You Need to Calculate Total Box Dimensions?

Calculating total box dimensions can help you a lot. Further, learning about “how to measure a box” provides you with plenty of packaging knowledge. Indeed, you can make bigger shipping boxes by just measuring the dimensions of your product boxes. Because mainly you sell your products to retail markets in bulk.

If you have an e-commerce website, even then, you mostly do wholesale business. For instance, if you have to sell jumbo Soap Packaging Boxes at Amazon or Etsy, then you need to make a bigger shipping box for them. With this, I will give the example of Candle Boxes.

If you sell candle boxes wholesale to a retailer, you cannot deliver each candle packaging box one by one to the wholesaler. You need a big shipping box to deliver the product boxes in bulk at one time. Let me show you how to make a big shipping box by measuring a single box dimension.

How to Make a Big Delivery Box by Measuring Box Dimension?

For instance, your candle packaging box has the following dimensions.

6” x 5” x 5”

LxWxH

The total cubic dimensions of this box are 150 cubic inches. Suppose you have to make a bigger shipping box to pack twelve candle boxes; then you should make the box of the following dimensions.

12.5” x 10.5” x 10.5”

L x W x H

Twelve and a half inches of length of the box will be enough to place two candle boxes. 0.5 inches extra space in inside dimensions will give you ease in placing two boxes side by side. Similarly, you should increase 0.5 inches of size from the width and height.

Hence, you can place candle packaging boxes easily in a shipping box. This is how knowing the inner and exterior box dimensions is helpful for you because transportation of packaging boxes is always indispensable.

When you place an order with a packaging company to make your packaging boxes, even then, you need shipping to bring the boxes to your location. But when you order at OXO Packaging, you don’t need to worry about shipping because shipping is free here.