A Guide on How to Manage a Packaging Inventory for Businesses

Managing a Packaging Inventory is one of the most overlooked aspects of running a business, yet it plays a crucial role in efficiency, cost management, and customer satisfaction. Whether you are a retail brand, eCommerce store, or manufacturer, improper packaging inventory management can lead to wasted resources, delayed shipments, and lost revenue.

If you are a business owner, you might be facing challenges for effective packaging inventory management. Read this blog to resolve the challenges, leverage benefits, and best practices of managing packaging inventory.

A Brief Overview of Packaging Inventory Management

Packaging inventory involves materials designed to package and ship products to customers or retailers. Materials such as boxes, lids, bottles, cans, and jars are part of the packaging inventory.

However, packaging inventory management is the process by which storage centers or warehouses store, locate, track, and reload these materials.

By indulging in effective packaging inventory management, your business streamlines efficient packing and preparation of products for shipping. However, an improperly managed packaging inventory can lead to delays, high costs, and inefficient daily operations.

Challenges of Inventory Management in Packaging

The process of effective packaging inventory management consumes time and effort. It needs a complete understanding of product flow throughout your facility. The proper management of packaging inventory also involves materials that are significant to secure and package them appropriately.

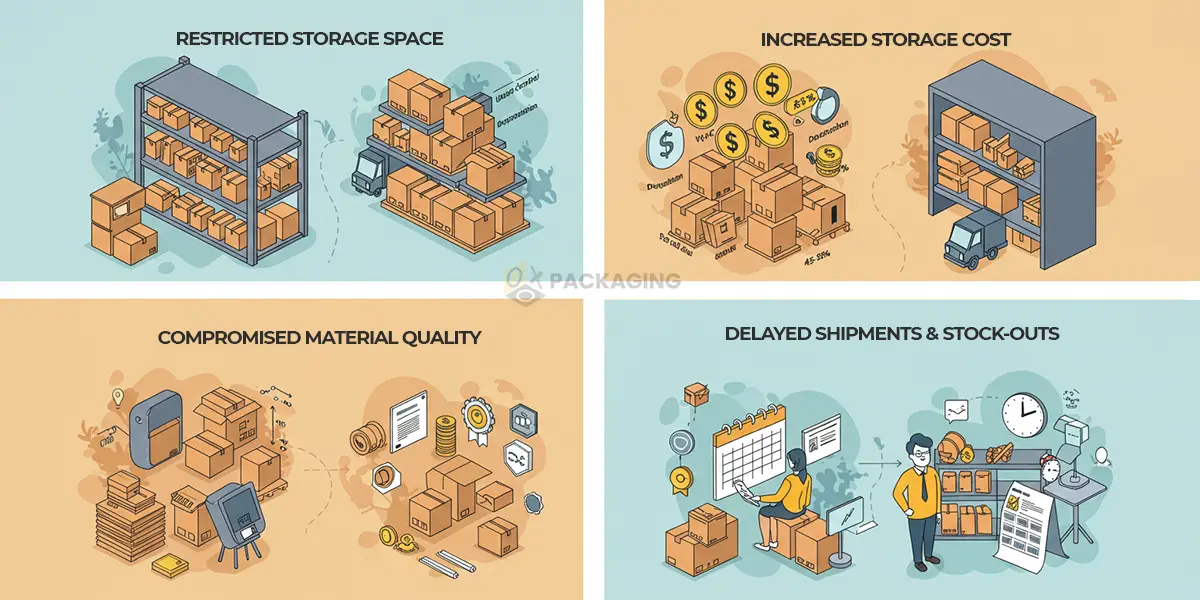

However, most businesses face major challenges when it comes to optimizing their product packaging and shipping approach during this process. Some of these challenges are:

Restricted Storage Space

One of the most popular challenges in packaging inventory management is a constrained space for storing your existing products. Many businesses struggle to maintain a well-optimized warehouse space because they require a high maintenance budget.

Contrarily, an effective packaging inventory system allows businesses to optimize available space and make the best use of facility resources. With this system, you can make well-informed decisions about space requirements for your warehouse.

Any manufacturer can leverage this system to get accurate insights when it is time to expand or move to a different warehousing space.

Increased Storage Costs

Improper packaging inventory leads to increased storage costs or high inventory holding costs. Poor space management for storing inventory leads to expensive storage costs. These costs are associated with unsold inventory in your warehouse.

Some factors such as insufficient space storage, product deterioration, climate control equipment, and security systems significantly contribute to these high inventory holding costs. This cost ranges between 45-55% of total inventory value and varies depending on your business size and industry.

However, by optimizing the above-mentioned factors, your business can overcome this challenge and reduce storage costs for inventory.

Compromised Materials Quality

Choosing consistent materials for your product packaging plays a crucial role in your branding and customer experience. But maintaining consistent materials to get desired outcomes can be challenging. You can choose packaging materials that don’t provide superior strength to products effectively compared to others.

Or simply your chosen materials might not match your previous packaging which can result in a poor customer experience. While packaging, inventory management systems help you get more consistent materials.

As a result, your products retain a consistent appearance when shipped to customers while boosting the packaging experience. Different businesses establish a strong and consistent brand identity by leveraging proper packaging inventory management.

Delayed Shipments and Stock-Outs

Imagine running out of packaging right before a big order is due. Or worse—overstocking bulky packaging that eats up your storage space and cash flow.

Running out of packaging means orders can’t be fulfilled on time, which creates frustration among your customers. Overstocking and stock-outs often result in financial losses and delayed shipments.

But an organized and efficient inventory management system ensures your business has an optimal number of products in stock which eliminates the risk of wasting space or running out of essential items. Hence, your business can streamline operations and ensure product shipping on time.

Also, you can optimize your supply chain connections and provide ample opportunities to increase your stock or fulfill your orders to meet customer’s demands.

Advantages of Proper Packaging Inventory Management

Despite the challenges of packaging inventory management, the best part is a proper system for effective packaging inventory management exists. This system brings a lot of benefits that help your business in many aspects. Have a look at them:

Reduced Costs

Proper packaging inventory management allows you to drive precise insights when it comes to ordering and warehousing costs. These insights help you to identify potential areas for cost-cutting and reduce waste.

Enhanced Efficiency

With effective inventory management, your business experiences streamlined operations to store and package products more rapidly. This operational efficiency reduces shipment delays and enhances timely decision-making.

Improved Quality

Enhance the inspection of packaging materials to boost quality control. You can identify potential quality control problems in advance and overcome them accordingly. Doing so will boost enhanced customer engagement and loyalty.

Supported Sustainability

Help your business build an ethical image by sourcing eco-friendly materials. These materials minimize packaging waste while contributing to green credentials and community well-being.

Enhanced Customer Experience

Get rid of delays caused by global supply chain disruptions or packaging material shortages. This leads to guaranteed delivery times and forbidden delays. As a result, you strengthen your brand identity and enhance customer service.

How to Manage a Packaging Inventory Effectively?

Since you have explored some of the main benefits of having the right packaging inventory system, let’s explore how your business can maximize profitability by managing a packaging inventory effectively.

Use Modern Inventory Management Systems

Leverage software tools to automate and digitize inventory processing while untapping the potential of modern inventory management systems. You can use tools like Zoho Inventory, Cin7, or NetSuite to consider both product and packaging inventory.

With modern inventory management systems, you can have a comprehensive assessment of your processing operations which streamlines management solutions. These systems offer supply chain prediction while enabling you to forecast potential delays and lead times. Enhance your product inventory management capabilities using these systems.

Implement Just-In-Time (JIT) Inventory Practices

Implement a Just-In-Time (JIT) system to optimize inventory management. Using this system you can order materials depending on your need while eliminating overstocking.

Let’s suppose you use a specific packaging box. The JIT system helps you monitor your inventory levels and usage needs for this material. Hence, you get real-time notifications when you are running out of required boxes ensuring you have sufficient boxes within the established time frame needed for packaging.

Do Regular Inventory Audits

It is crucial to perform audits for your existing inventory on a regular basis to effectively manage your packaging inventory. Regular audits also help you lower high-holding inventory costs. Leveraging these audits allows you to find overlooked corners where excess materials and backups are placed.

Here chances of missing materials may have increased significantly which regular audits prevent. These audits allow you to track every material lying in your warehouse while minimizing waste. So you identify and eliminate unnecessary spending with an accurate picture of your present inventory levels.

Upgrade Storage Solutions

Warehousing space is costly as mentioned earlier. However, failing to optimize this space can result in unnecessary spending. Incorporating effective storage solutions enables you to maximize the available space while eliminating the need for occupying extra floor space.

Consider using compact packaging materials such as collapsible corrugated boxes to minimize the footprint of stored products. With a thoughtful and creative approach to your storage, you can make the best use of your budget and warehousing space.

Work with a Reliable Packaging Supplier

The supply chain serves as the backbone of any manufacturing business. So developing a basic understanding of its dynamics is crucial to protect the essential supplies within the established timeframe for product production and customer deliveries. Enhance supply chain processes and enjoy growth opportunities by investing in supplier relationships.

By working with a reliable packaging supplier, you can get consistent packaging materials, fast time turnaround, and streamlined packaging operations. Doing so allows you to use innovative materials to improve packaging and expand your supply chain network which leads to operational improvements.

Optimize Your Packaging Inventory Management Now

The importance of delivering products to customers in a timely manner is crucial for you as a business owner. But fulfilling the requirements required to create exceptional packaging inventory management systems is easier said than done. OXO Packaging is here to help you streamline product packaging and shipping operations. Whether you are a small startup or a well-established brand, we partner with businesses like yours to optimize operational efficiency.