A Guide to Packaging Solutions for 5 Major Industries

The custom packaging industry is growing rapidly due to its high market demand. According to a report shared by Market Research Future:

“The custom packaging industry is expected to grow from US$ 54.92 billion in 2024 to US$ 72.63 billion by 2032, at a CAGR 3.5%.”

Packaging is used in nearly all the product-based industries. It not only protects the goods and commodities but also showcases brand elements to fascinate consumers. The wide range of packaging uses results in the need for multiple types of packaging for every industry.

In this blog, we will discuss a detailed guide about packaging solutions for 5 major industries. We’ll also explore the importance of industrial packaging as well. Read on to find more!

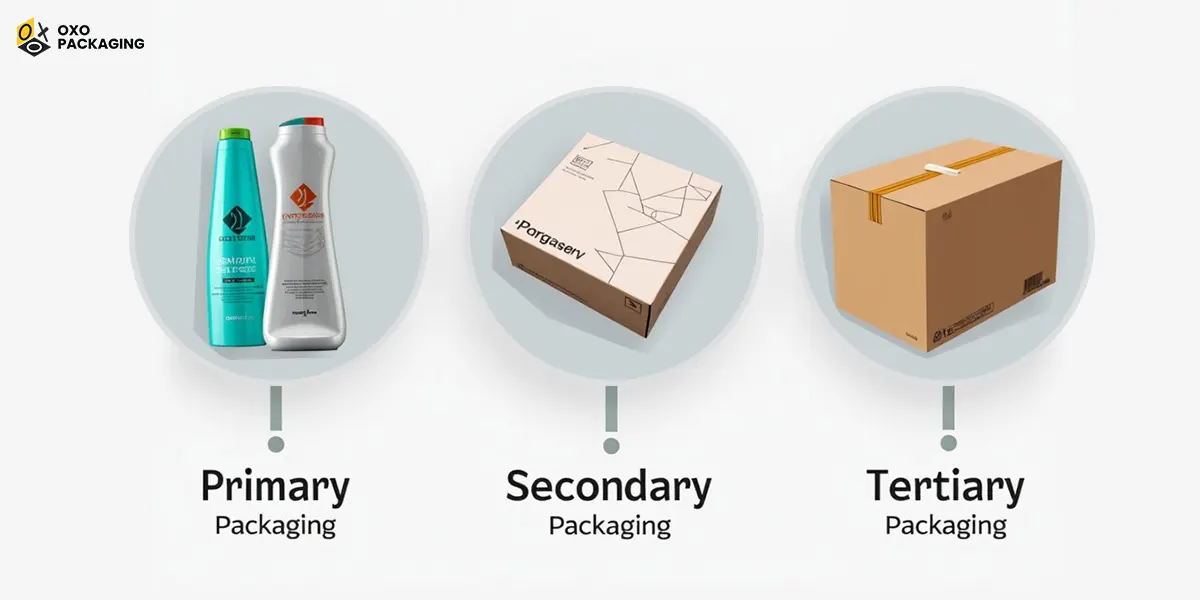

3 Fundamental Types of Industrial Packaging

Custom packaging can be categorized based on many factors. For instance, many types of packaging materials and styles are used based on their features. However, there are 3 fundamental types of industrial packaging that you must know:

Primary Packaging

Primary packaging is the essential one that comes in direct contact with products. It is the first barrier that keeps the product safe and sound. This packaging is designed to provide significant protection to items packed inside and to be conveniently opened by the consumers.

Tin packaging and tailored mylar bags are mostly used in the retail industry for product packaging. Other options like plastic or glass bottles, polythene bags, and sometimes tailored cardstock boxes also serve as primary packaging.

Secondary Packaging

Secondary packaging is used to pack primary packaging. It provides a second line of protection to the products and is also persuasively tailored so it looks fascinating on the retail shelves. Cardboard, kraft, and corrugated boxes are common secondary packaging for most products.

These boxes are designed to accommodate multiple products packed in the primary packaging making them perfect for selling purposes.

Tertiary Packaging

Tertiary packaging is an important yet final packaging of a supply chain. The significance of this packaging type lies in its sturdy make. The reason is that it protects the products from bumps, knocks, and other environmental factors, during shipment.

Robust shipping boxes are the best example of tertiary packaging that helps ship products in cargo and trucks. Corrugated stock is considered to be excellent for making tertiary boxes. The reason is that corrugated flutes provide cushioning protection to items packed inside.

Custom Packaging for 5 Different Industries

Product packaging can be customized for any industry. However, 5 major industries cover the major share when it comes to the usage of packaging. Here are the five categories of packaging based on the industries in which they are used:

Electronics Packaging

Packaging for electronics includes enclosures that protect electronic products and present them engagingly to the prospects. Electronic devices, whether home appliances, smart gadgets, or electronics for commercial use, need suitable packaging for keeping and shipping.

Packaging for electronic devices should be equipped with suitable features that ensure product safety. Also, they should be easy to customize so that retailers can present them appropriately to prospects.

Here are some of the vital properties that every electronic packaging must have:

Durable Packaging Materials

A sturdy packaging option prevents products from the bumps and knocks of shipping. When it comes to electronics, these items are fragile and can easily break if encountered with knocks.

Cardboard and corrugated board are most commonly used to pack such fragile items. The reason is that both these materials are robust and ideal for avoiding bumps of shipping and handling. Added features like bubble wraps, styrofoam, and more provide extra protection to electronics.

Thermal Dissipation

Electronic items are prone to get damaged due to overheating. To address this issue, manufacturers and suppliers need thermal-resistant packaging. The heat coming from the environment or generated by the device can be hazardous for the device. Manufacturers mostly build cooling systems that dissipate the heat generated from the device.

However, when it comes to heat coming from outside appropriate packaging is needed to address this problem. A properly ventilated yet unblocking packaging material can help you with this. You can use perforated paper-based boxes for electronics that block the environmental heat and dissipate the heat entrapped inside the device with its perforations.

Electromagnetic Shielding

Electromagnetic waves are not good for devices having a precisely crafted circuit that follows standardized charge measurements to operate. For such devices, you would need electromagnetic shielding or canceling features in your packaging. EMI shielding bags and pouches are available that serve the purposes of blocking electromagnetic waves efficiently.

Ideal Boxes to Pack Electronics

As discussed above, cardboard or corrugated boxes are excellent when it comes to packing and shipping electronics. However, you would need added features such as bubble wrap or styrofoam for added protection of electronics.

For high-end electronic devices, die-cut foam inserts can also be used to enhance the overall appeal of your electronic packaging.

Pharmaceutical Packaging

Custom pharmaceutical packaging is used to pack and secure pharmaceutical drugs. Medicines and ointments need to be packed suitably so that they are safe to be consumed. Also, appropriate packaging can enhance the shelf-life of a medicine extending its expiry date.

What is Sterile Packaging?

Sterile packaging is one of the safest and most reliable packaging options for medicines. The reason is that these packaging solutions are made such that they do not add contaminants to the medicine. So, the medicines packed inside them are safe to be used.

The ideal example of this packaging includes sterile coextruded films. They are lined inside some pharmaceutical packaging to make them contaminant-free and safe for consumers. These films are made from HDPE or PP plastics giving them a robust make.

Types of Packaging for Pharmaceuticals

Many types of packaging can be used to enclose medicines safely. Some of the most reliable and common packaging options are listed here:

- Boxes: Cardboard and corrugated boxes serve as exceptional secondary packaging for the medicines. Whether you want to pack bottles, blisters, or more, you can conveniently enclose them in a tailored cardstock box. You can also print important information about the medicine and its usage on these boxes for ultimate compliance.

- Bottles: Glass bottles are perfect non-reactive packaging options for medicinal tablets and syrups. This type of packaging does not add any toxins to the medicines even in high temperatures. Bottles are also easy to open and used by the users.

- Blisters: Blisters are another ideal packaging choice for packaging tablets and capsules. These packaging options are made to provide convenience to users in using them. The blisters are mostly made from PVC, and a metalized film backs these blisters.

- Sachets: Sachets are mostly used to pack medicines that come in powdered or grain form. These are mostly tiny plastic bags, or mylar pouches that are heat-sealed. The heat sealing makes this packaging resist the air and humidity of the environment enhancing its shelf-life.

- Ampules: Ampules are perfect for packing liquid medicines that are good for one-time use only. The injectable medicines and orally consumable medicines are mostly packed in these packaging solutions. Ampules help you pack medicine in an accurate dosage that most patients are required to consume. It avoids the risk of overdosing and the effects associated with this act.

Source: Origin ltd

Food and Beverage Packaging

Choosing the right packaging in the food and beverage industry is important. A wide range of food products are there in this industry that need individualized packaging based on the product needs. Tailoring your packaging for food & beverages is the best option to avoid hassle.

Here are some common packaging types you can pick from according to your specific needs.

Kraft or Corrugated Food Boxes

Kraft and corrugated stock are reliable packaging materials that are considered safe for food packaging. The reason is that both these materials are wood-based, and we know that wood doesn’t harm our health.

Also, kraft or corrugated packaging boxes are long-lasting and biodegradable food packaging. So, they can keep your food items fresh for a long time without hassle and are good for the environment as well. These packaging options are also customizable allowing you to use them for branding of your food business.

Glass or Plastic Bottles

Glass and plastic bottles are mostly used to pack beverages and water. Both the items can be instantly consumed and even stored for a long time in bottle packaging. Oils, sauces, and other liquid food items can also be packed in bottles.

Custom Mylar Bags

Mylar is another reliable material that helps you make perfect packaging for many food items. This type of packaging is more suitable to keep processed food consumable for long. Mylar bags for food storage are made with a blend of plastic and metallic foil. Both the materials have tear-resistant and water-resistant properties making them ideal for food packaging.

Edible Packaging is the New Trend!

In the food industry, a new trend of using edible packaging has become highly popular. These packaging solutions are safe to be consumed by consumers. Rice, potato, and seaweed-based food bags are becoming popular. Starch-based straws and plates are also some trendsetters in the food and packaging industry.

Retail and E-Commerce Packaging

Personalized retail packaging and e-commerce packaging are widely used across various industries. Endless retail products are out there that need appropriate product packaging for their specific needs. When it comes to the retail market, branded boxes and display packaging are commonly used.

The reason is that businesses want retail products to grab the attention of prospects. So, packaging for these products is designed considering the target audience and buyer journey.

On the other hand, e-commerce products mostly come in the form of branded mailer boxes. Ensuring the safe shipment of the products and boosting the brand are the prime concerns of e-commerce businesses.

Here are some ideal packaging solutions that are used in retail and e-commerce industries.

Branded Retail Packaging

Branded retail packaging is customized according to the dimensions of products packed inside it. Printing is an important element that adds a touch of elegance to this packaging and makes it branded. Businesses add their brand logo and choose the right color scheme for this packaging for marketing purposes.

Personalized Mailer Boxes

Mailer packaging boxes are perfect for packing and shipping e-commerce products. These boxes are mostly made of corrugated material. The robust makes is one of the primary reasons that these boxes are safe for the shipping of e-commerce products. If you are an e-commerce business, you can print your brand logo on these boxes. It’ll reinforce your brand identity in the minds of your buyers.

Display Packaging Boxes

Attracting customers on the very first sight is important if you want to boost your sales. To do so, you can use custom display boxes in a retail environment. These captivating boxes not only engage your prospects but also persuade them to buy your products. Boxes with die-cut windows and countertop display boxes are some common examples of retail display packaging.

Cosmetic and Beauty Product Packaging

Cosmetic packaging is the need of the hour for the beauty product industry. Custom cosmetic boxes are mostly used as secondary packaging for cosmetic items. These boxes are mostly made of elegant and customizable materials like cardboard and kraft.

Both these materials not only protect cosmetics but also showcase them elegantly to the customers. Businesses print their brand logo and other persuasive graphics on these boxes to make them a marketing tool.

Apart from boxes bottles, tins, tubes, and tinctures are also used to pack cosmetic products. All these options serve as primary packaging. They are made such that items packed inside them are easy to be used by the consumers.

Customization is paramount when it comes to the packaging of the cosmetic industry. The reason is that standing out as a brand is essential for cosmetic and beauty product businesses to generate more revenue. Here are some easy ways to customize your cosmetic packaging:

Think of Product Safety

Delivering your cosmetics in pristine condition is essential if you want to earn maximum customer satisfaction. To do so, opt for a durable and reliable packaging that enhances the shelf-life of your products. Custom boxes, sealed bottles, or tins are some suitable options to consider.

Never Overlook Your Target Audience

Your packaging design must resonate with your target audience. It helps you fascinate the right customers for your products. Print suitable graphics on your cosmetic packaging that relate to your target audience and persuade them to buy your items.

Pay Attention to Branding

Displaying your brand on your cosmetic packaging can help you showcase the uniqueness of your business to prospects. To do so, you can benefit from a quality printing technique to print brand elements on your cosmetic packaging. Brand logos, taglines, and color schemes are important elements that you can print on your cosmetic boxes.

The Importance of Industrial Packaging

The significance of industrial packaging can’t be denied. This packaging is crucial when it comes to streamlining your supply chain of a product-based business. Here are some of the benefits that you can enjoy if you customize industrial packaging:

Convenient Storage & Shipping

Delivering products safely to the inventory, retail stores, or customers is paramount for businesses. Many types of mailer boxes are available that ensure convenient shipment of e-commerce and retail products. Corrugated and cardboard boxes are mostly used for delivery purposes. The reason is that these boxes protect products and are easy to stack in cargo or shipping vehicles.

Customized Packaging Solutions

Industrial packaging is mostly made of flexible material. You can easily alter their shapes and sizes according to your preferences. Personalizing them to your product dimensions is quite easy. You can also print these packaging solutions according to your needs. You can print your product boxes and bags with your brand elements making these packaging options resonate with your brand.

Durable Packaging Ensures Safety

Robust packaging is the need of the hour for businesses that ensure product safety. Keeping items pristine till they reach the hands of customers not only prevents losses but also satisfies customers. You can choose from cardboard, rigid, or corrugated boxes with added protective inserts for your product packaging. That’s how reliable packaging ensures product safety irrespective of which industry it is in.

Customize Product Packaging for Any Industries

Customizing product packaging according to your relevant industry standards is paramount if you want to grow your business. A credible packaging company can help you in this regard. The reason is that a reliable company not only ensures packaging quality but also caters to your specific needs.

You can partner with OXO Packaging for all your packaging needs. We personalize custom packaging solutions for nearly all industries. From tailoring shapes and sizes to customizing finishes and prints, we offer comprehensive customization options.

Also, you can enjoy various benefits like free shipping, fast turnaround, low MOQ, and free design support from us. Get in touch with us today to customize your packaging.

Conclusion

Now you know which types of packaging will be suitable for different industries. We have discussed in detail 5 of the major industries that need robust and reliable custom packaging for their products. If you still have any questions or want to get a quote for your required packaging, reach out to OXO Packaging. We are always here to answer your queries and customize the perfect packaging to your needs. Happy Packaging!