6 Prevailing Packaging Technologies in 2025

Addressing modern problems and enhancing the customer experience give rise to innovations in the packaging industry. Whether you are a startup or an established enterprise, staying informed about these technologies and innovations helps you upgrade your packaging game.

But, how can you design your packaging that meets modern styles and sustainability goals? Here are 6 prevailing packaging technologies that you should know in 2025 to stay ahead of the curve. Read on!

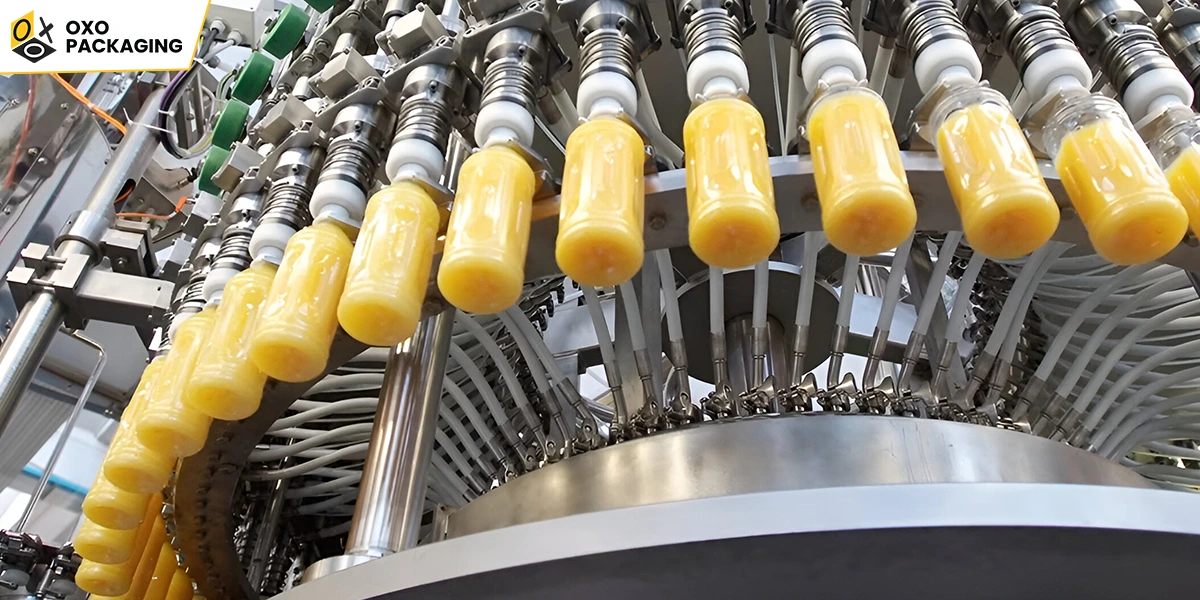

Automated Packaging Systems

Packaging automation is the process that allows the packing or filling of products to be handled by robots with minimal or no manual effort. A wide range of machinery is available to carry out such tasks. The machine you choose depends upon your individualized product packaging requirements.

Automated packaging entered the market in 1961 when a machine that could fill and seal bags was created. The tremendous evolution of packaging automation systems can be witnessed over time. From simple sealing and labeling processes to picking, placing, boxing, and palletizing, various aspects of automation have evolved.

Importance of Packaging Automation

The significance of packaging automation can’t be overlooked. When you are dealing with FMCGs, electronics, apparel, and other goods at a large scale, automation significantly reduces cost and effort. Incorporating robotics in the processes allows you to pack thousands of products and make them ready to sell within days or even hours.

Automation also minimizes the chances of errors and omissions when packing products. The reason is that programmed machines do not have limitations that cause errors as manual workers have.

However, the type of automation you need comes with its distinctive requirements. For instance, automated packaging systems for filling bottles are different from those for cartoning. Here are some packaging automation systems that meet individualized packaging needs:

Fill & Seal Machines

Considering the high demand for beverages and other liquid products like syrups and sauces, optimizing bottle packaging of such products can be overwhelming. Filling & sealing machines can play an important role in this regard. These machines are designed to fill all bottles in equal proportion and seal them automatically.

Packaging machines like a cartoner or folder gluer by ELITER Packaging Machinery can help you manage the complex process of folding and sealing easily. Such machines can run the cartons from blank to a formed carton that can be loaded with products.

These machines make light work of complex processes by taking advantage of guides and rails to mechanically fold and cockle flaps and panels of the blank cartons. But to ensure that you get desired results from these machines, you must get boxes that have amazing strength and are sturdy. Highly sturdy boxes will ensure the machine's consistent operation and you’ll get reliable boxes in return.

Carton Sealing & Tapers

Arranging cartons, packing products inside them, and sealing the boxes is a matter of great importance. The cartoning process can be automated with the help of cartoning machines. All you need to do is fill the compartments of these machines with your products and folded cartons.

The machines unfold your cardboard or corrugated box cartons, pack products inside them,m and automatically seal them. Some machines even use robotic carriers to stack cartons for shipping purposes.

Automated Film Wrapping

Fruits, vegetables, and similar items are mostly wrapped in polythene films to keep fresh for a long time. These films can be wrapped around these products with the help of automated machines. Such machines not only fetch wrapping material but also wrap it around your products, cut the film, and seal it.

Automation of wrapping systems brings you endless benefits. First and foremost, it reduces the wastage of packaging material, as it uses wraps in a well-programmed quantity. Also, the chances of tears in the wrapping sheets are also reduced by many folds.

Recycling Automation

The increased demand for sustainable packaging has enhanced the importance of recycling the process. To recycle packaging materials without compromising their quality can be a daunting task if done at a large scale. You can benefit from automation to carry out the recycling process seamlessly.

This process involves shredding packaging materials like kraft, cardboard, and corrugated cardboard. After the material is shredded, it is transferred to the bleaching and recycling parts of the automated system. That’s how recycling machines help you automate the recycling of product packaging without hassle.

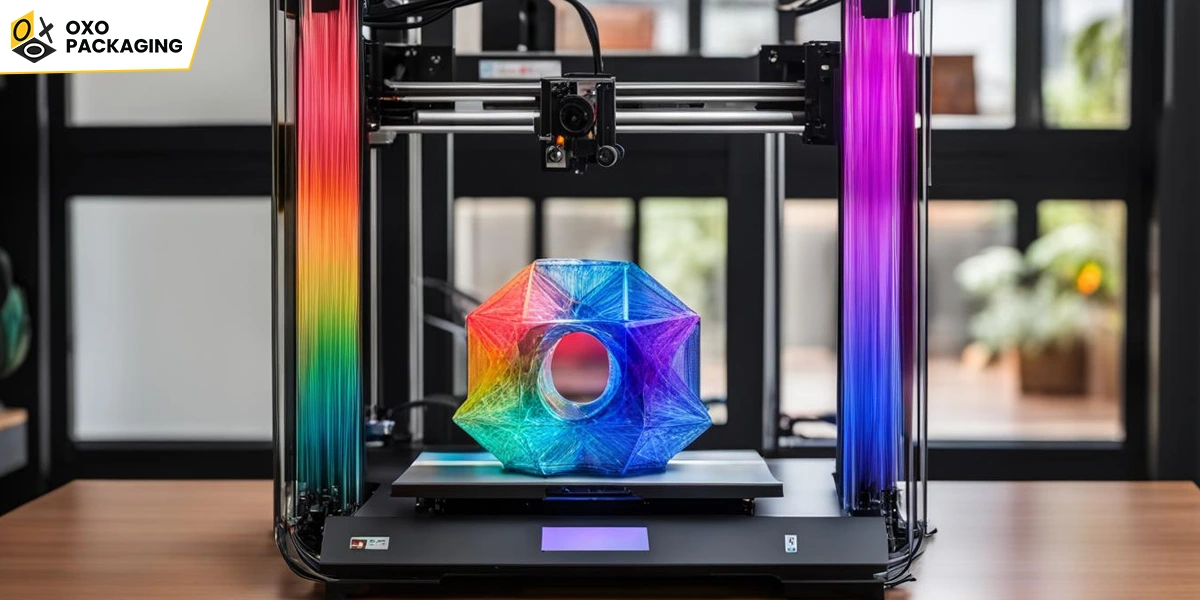

3D Printing in Packaging Design

One of the most advanced printing techniques that help you enhance the functionality and visual appeal of your packaging is 3D printing. This exclusive printing technique does much more than just adding 3D graphics on your boxes. You can also use this technique to personalize the inserts and outlook of your product boxes without hassle.

Packaging Material Suitable for 3D Printing

Before exploring 3D printing machines that are used in the packaging industry, let’s explore packaging materials that can be printed using these techniques. Paper, fabric, or wood-based materials are not the best material options if you want to create a 3D print.

You can use plastic-based materials like vinyl, acrylic, etc. to enhance the captivity of your packaging with 3D printing. Tin can also be printed with the help of 3D techniques. Such unique printing options allow you to personalize the packaging design for new advertising campaigns like PepsiCo & Marvel Studios did.

Case-Study:

PepsiCo and Marvel Studios partnered to create a campaign before the premiere of “Black Panther”. By benefiting from the 3D printing services of “Protolabs”, a Black Panther mask was created that fit onto the newly designed Pepsi can.

3D Printers for Packaging

A range of 3D printers are available in the market that can help you create timeless packaging for your products. The type of printer you choose depends upon your individualized needs. Whether you want to create hard packaging with 3D printing techniques, or custom inserts for packaging boxes, explore these printing techniques:

- Stereo Lithography (SLA): SLA printers use lasers to convert liquid resin into plastic. This process is called photopolymerization. This method helps you package your desired designs without any hassle.

- Selective Laser Sintering (SLS): These printers use a laser to sinter polymer powder into a solid structure like tin. The unfused powder helps in printing. This 3D printer is mostly used to print beverage cans.

- Fused Deposition Modeling (FDM): These printers extrude thermoplastic filaments, such as PLA (Polylactic Acid) with the help of a heated nozzle. This process melts down the material and applies the plastic layer by layer on the packaging material.

Tamper-Evident Packaging Technologies

Keeping products securely packed inside the product packaging is essential for the manufacturers and brands. To do so, you can benefit from tamper-evident packaging features. Such features leave a mark if anyone opens the product packaging.

Using such protective packaging brings you endless benefits. First and foremost, tamper-evident packaging ensures that your products can’t be accessed by anyone other than buyers. Also, incorporating such safety features into your product packaging helps you get the trust of your buyers.

Various technologies for tamper-evident packaging can be used depending on your specific needs. The type of seal you choose varies depending on the industries, styles, and packaging material.

FDA Tamper Evident Packaging Requirements for Food

FDA recommends tamper-resistant packaging for some over-the-counter drugs. If you sell such items, it is mandatory for you to create product packaging according to such guidelines. According to these guidelines, you need to use a packaging for your drugs (as mentioned in the regulation) that comes with an indicator to enter in the packaging.

If you are looking for the right tamper-evident packaging for your products. Here are some reliable options to pick from:

-

Blister Packaging

This type of packaging is famous for its cost-effective yet reliable packaging features for small-sized drugs. You can pack medicinal tablets in these packets without any worries. This packaging option comprises clear blisters to showcase tablets backed by a plain sheet of aluminum foil.

Users can’t access the tablets without tearing the aluminum foil, and once torn, the foil can’t be reattached. That’s how this packaging leaves evidence of whether someone accessed products or not.

-

Pressure-Sensitive Foam Seals

Pressure-sensitive foam seals are mostly used to cover bottled products. This type of sealing covers the opening of bottles under the cap. Pressure-sensitive foams can’t be opened without tearing. So, a torn foam seal means someone has accessed the products packed inside these bottles.

-

Caps with Tamper-Evident Bands

This is another tamper-evident feature that is most commonly used for medicinal syrups and beverages. Tamper-evident seal bands are attached to the caps of the bottles. When someone opens the bottles, the seal band breaks its connection with the cap. If you find the seals detached from the cap, it signifies the bottle has been opened.

Nanotechnology in Product Packaging

Nanotechnology is an extremely small-sized aspect of the packaging materials that enhance the overall functionality and aesthetic appeal of the packaging. This technology brings innovative benefits to your business. Some of the most common nanotechnologies prevailing in the packaging industry are listed here:

-

Nano Cellulose

Nanocellulose is a plant-based material, however, modified to some extent. Nanostructured cellulose bears distinctive properties that regular cellulose doesn’t. For instance, this exclusive cellulose is a denser and stronger packaging material. The surface of such cellulose is also impermeable to water and other liquids.

Although Nano cellulose bears all these remarkable features, it's not as dangerous as plastic. The reason is that it is made of biodegradable and compostable material. So, it leaves no carbon footprint behind to pollute the environment.

-

Nano Starch

Starch is made of two polymers: amylose and amylopectin. Both combine to create a strong and robust material that comes with endless benefits. However, Nano starch is more durable and flexible than regular starch. The reason is that this material is further processed to add strength to it.

Distinctive features of Nano starch-based packaging include biodegradability, water impermeability, and thermal barrier.

-

Carbon Nanotubes

One of the most robust materials you can use for packaging is carbon polymer. A cylindrical form of carbon having a diameter in the range of nanometers is called a carbon nanotube. The mechanical and antimicrobial properties of this packaging material make it stand out from other packaging materials.

These nanotubes can also be used in the formation of oxygen sensors that monitor the concentration of oxygen in modified atmospheric packaging.

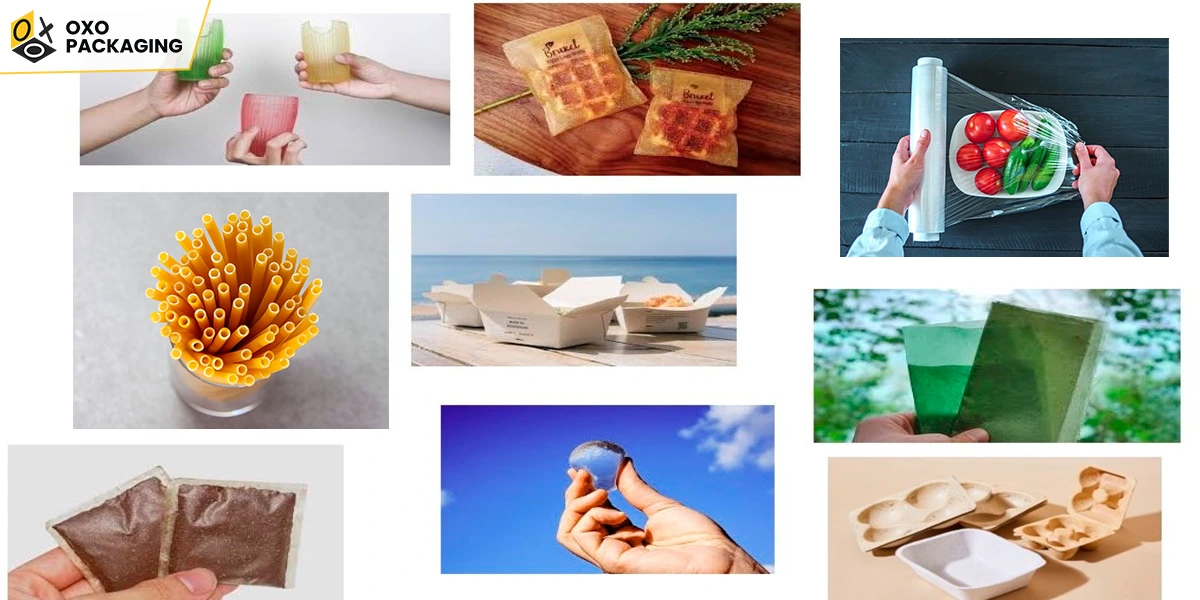

Edible Packaging Innovations

The trends of edible product packaging are continuously rising due to its undeniable features. Considering the harms of plastic packaging, food brands look for a type of packaging that is harmless to the health of consumers. Here are some edible packaging innovations for you to pick from for your food packaging:

-

Starch-Based Food Films

Starch-based food films are considered to be an excellent alternative to plastic wraps. If you want to keep your vegetables, fruits, candies, etc. safer, choose these films to wrap your food items. The reason is that starch is a plant-based material that helps you make edible, biodegradable, and compostable packaging for your products.

With all the sustainable features, the strength and durability of packaging are never compromised with starch-based packaging.

-

Robust Pastas as Straws

Straws made from pasta are a reliable alternative to plastic-based straws. The reason is these straws are more robust than paper straws and biodegradable as well. The edible features of these straws make them excellent for using them for beverage consumption.

-

Edible Bottles of Seaweed and Calcium Chloride

Seaweed and calcium chloride can be blended to make thin films resembling plastic in properties. This packaging material can be used to make bottles for keeping beverages and other liquid items safe. Such bottles are 100% safe to be consumed by the users.

“Ooho” is an approach aimed at replacing plastic bottles with sustainable ones. Edible bottles completely coincide with the idea of Ooho.

Future Trends of Edible Packaging

The importance of edible packaging is increasing in the market. Considering the endless benefits of this type of packaging, more food brands are becoming inclined toward using edible packaging. According to Fortune Business Insights:

“The global volume of edible packaging was around USD 711.09 million in 2023 and is expected to rise to USD 1,193.98 million by 2032, exhibiting a CAGR of 6.02%.”

Popular Sustainable Packaging Technologies

Considering the rise in pollution and climate change, users prefer to buy products packed in sustainable packaging solutions. That’s where the demand for innovation in the sustainable packaging market has increased by many folds. Here are some popular sustainable packaging technologies that must not be overlooked:

Mushroom-Based Foam Inserts

Styrofoam is a non-sustainable material option for your packaging inserts. If you want to opt for a sustainable option instead, go for mushroom-based packaging inserts. These inserts are 100% biodegradable and compostable. Leaving no carbon footprint, they say a big hello to the greener future of our planet.

Case Study:

IKEA replaced Styrofoam with mushroom foam inserts in 2019 as a commitment to sustainability in their business practices.

100% Biodegradable Paper Packaging

When it comes to reliable packaging materials with sustainable features, nothing can beat biodegradable paper-based materials. Reduced cardboard & Kraft are considered to be 100% biodegradable materials leaving no carbon footprint.

However, packaging innovations like bioplastics have earned more popularity due to their durable and water-resistant properties like plastic and ultimate biodegradability

Repurposing Ocean Pollutants

Ocean pollutants that are harmful to water life and also waste resources of our planet can be repurposed. Ocean waste can be recycled and converted into recycled packaging. This approach not only helps reduce carbon footprint but also saves biohabitat in water bodies.

Wrap Up!

Packaging needs and trends are evolving, and so are the packaging technologies. Staying informed about innovations and trends is essential if you want to create exclusive packaging for your products. We hope that the guide on the above 6 packaging technologies will help you make suitable packaging for your products.

If you still have any questions or want to customize packaging for your products, reach out to OXO Packaging today!