Thinking Where Can I Buy EVA Foam? Answer is Here!

Rubber-like foam Ethylene Vinyl Acetate (EVA), sometimes called Poly Ethylene Acetate (PEVA) is a great option in producing your business products and/or your product packaging. Or you can use this foam if you are a hobbyist and want to ace the upcoming cosplay show. Read this blog to learn if you worry about where I can buy EVA Foam.

What Is Ethylene Vinyl Acetate (EVA) Foam?

Before going into detail about your query ‘Where can I buy EVA foam?’ It is better to discuss what EVA material foam is and the distinction between EVA vs Polyethylene foam. Ethylene Vinyl Acetate (EVA) or Poly Ethylene Acetate (PEVA) are rubber-like foam. These are ideal for providing a soft, lightweight, and protective layer to the products in packaging, especially during transportation and shipment.

Where Can I Buy EVA Foam?

You can explore online to find eva foam from online stores. Buying online is a suitable option for hobbyists. For example, if you are going to use eva foam for cosplaying purposes, you’re better off relying on the online stores.

But keep in mind that online stores don’t provide personalized eva foam options. In case of specific needs, relying on the online store for eva foam won’t be a suitable option. This is why you are better off contacting a packaging company for your eva foam needs.

You can place an order with a packaging company that can provide you with the quality eva foam for packaging or producing products. Such stores provide options like cost-efficiency in providing your requirements at your doorsteps without charging any cost of shipment, or supporting you with 100% waiver in setup of die and plate charges, and so on…

Why Do You Need to Use EVA Foam?

EVA acetate foam is a soft, lightweight, and protective material to provides a complete solution to your high-value products and gives your products a luxurious look with special care for your precious items. This material is highly in use in different industries to manufacture high in demand products of different industries.

Observe the following to have a better understanding of how largely this material is being used in the industry:

High Density

Ethylene Vinyl Acetate has a high density increasing the durability of this material. This material provides a great experience in increasing the life span of products packed and secured in EVA foam.

Cost Efficient due to Lightweight

PEVA (Polyethylene Vinyl Acetate) foam provides cost-efficiency to your product's shipment and transportation due to their lightweight, yet highly effective in reducing damages and losses in transit.

Soft, Durable, and Protective

Due high shock-absorbing properties of this soft and highly durable foam enhance protection to your products. This will help you satisfy your customers with special care and provide your customers with a secure delivery to their doorstep without causing any harm to the products.

Used In Luxury Packaging

This EVA or PEVA material increases attraction to your products with the packaging and supports you in raising the perceived value of your products. High perceived value allows you to persuade your prospect to buy your products and causes an increase in your sales.

Suitable for different products

EVA, vinyl ethylene is an expanded rubber or foam rubber and is used for different products in different industries, like the sports industry. The Sports industry gets benefits from EVA material in multiple products, like producing protective gear, hockey pads, shoe soles, foam mats for yoga or exercise, and furniture seating and cushioning.

EVA Foam Comparison with Other Foam Options

There are many other foam choices to use as the base material, add-ons, and inserts to add protection, attraction, and value enhancement to your products. Here is how EVA foam stands different from other foam options:

Polyethylene (EPE) Foam

Polyethylene Foam (EPE) is featured with the medium density that provides comparatively low protection to your products, and light in weight to produce cost efficiency, and available in black, white, and pink colors to provide you an opportunity to use this as your products require.

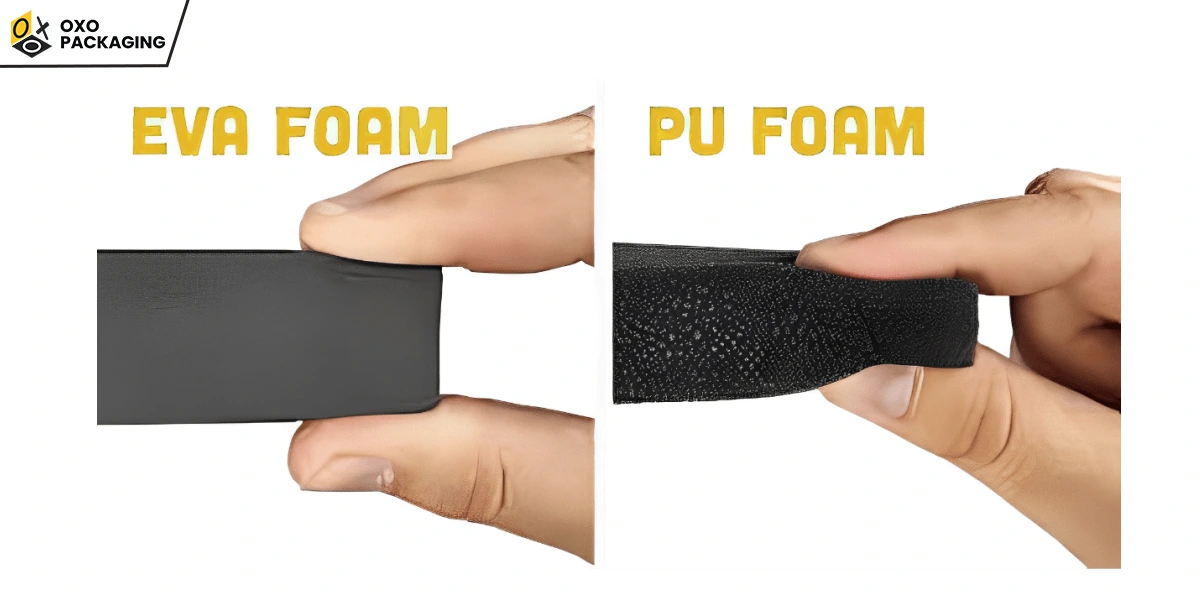

Polyurethane (PU) Foam

Polyurethane Foam (PU) is of low density providing less durability and strength to your product protection. This is lightweight too to enhance the benefits of reducing your shipment costs and providing you convenience. This PU foam is available in black, white, gray, and yellow color options, you can select as suits you the best to your product requirements.

Ethylene Vinyl Acetate (EVA) Foam

EVA Foam provides you with highly durable packaging enhancing the protection of your precious products with the high density of this material. This material is heavy-weight and comparatively more protective than other foam choices. You can increase the attraction of your boxed products with the black and white color options EVA foam inserts and cushions to delight your customers.

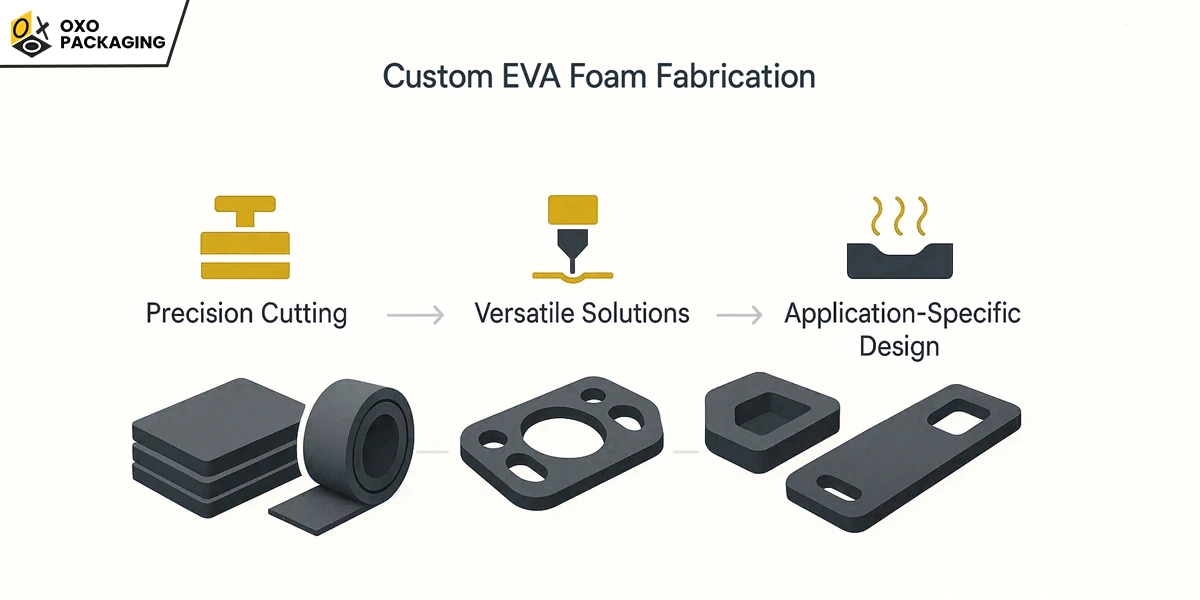

What is Foam Fabrication?

Foam fabrication is the process of forming foams from the polymers to the versatile shape and style of this foam material. You can use different fabrication methods to produce high-quality EVA foam using any of the available fabrication methods.

What Are Fabrication Methods of EVA Foam?

Fabrication method of producing foam in desired shapes, styles, and sizes provides you an opportunity to meet your products or packaging requirements. Any of the following fabrication methods can be applied according to the specific needs of your business and product packaging. Let’s see the available fabrication options to enlighten your mind with the fabrication methods:

Water-Jet Cut

The Water-Jet Cut fabrication method of EVA foam uses high pressure of water to produce the desired results in shapes and sizes. This fabrication method is best suited to produce extremely accurate shapes of the output you require as per your specific requirements.

Laser Cut

Laser is a great choice of EVA foam fabrication method to produce highly desirable output using a high-power laser beam to cut and vaporize foam for smooth edges. This is one of the smart and modern techniques to produce effective and desired results for your products or product’s packaging requirements.

Knife Router Cut

Knife Router Cut fabrication method is used with the help of a router bit or knife to cut the shape and size to your business or packaging products requirements. You can use this fabrication method when you are in need to produce prototyping (3D printing application or foam model). This type of fabrication fits when you are less concerned with a precise finish to the output.

Wire Cut

By using a heated metal wire to create an output of this EVA foam in shape, style, and size you can also use the wire cut method of foam fabrication. This heated process helps in melting and vaporizing foam to create a clean and crisp cut to your EVA foam.

Die Cut

Die Cut is also another good choice to produce simple two-dimensional cutouts. This method of foam fabrication is used with a series of dies to produce the desired results from your fabrication method of your business of products requirements.