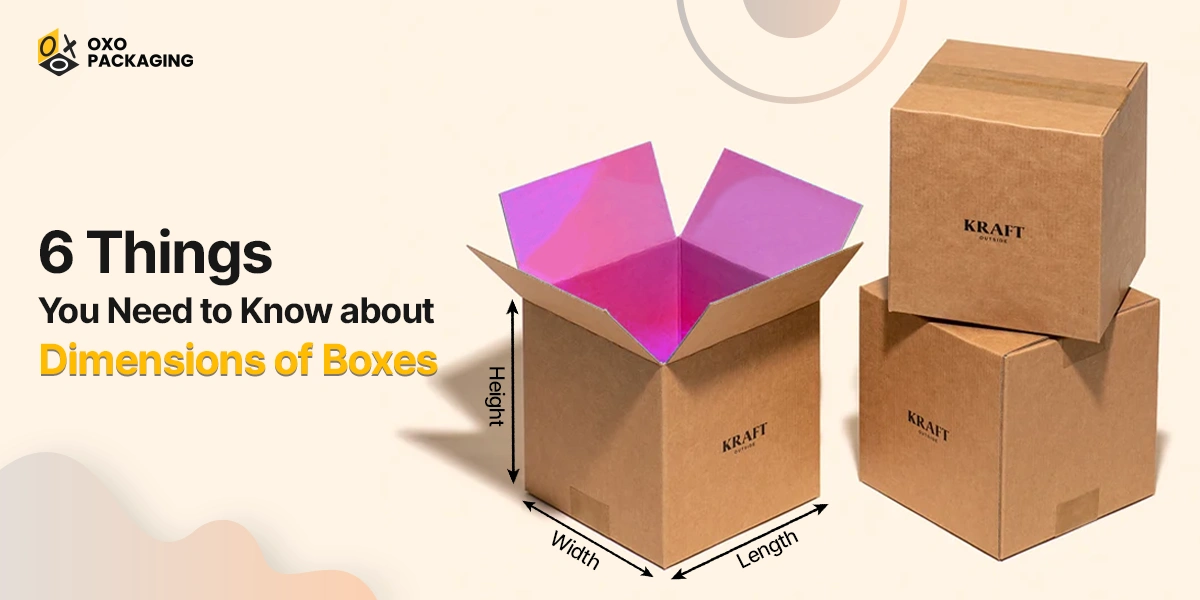

6 Things You Need to Know about a Dimension of Box

Measurements of the 3 dimensions of boxes are important to learn when deciding your custom boxes. Generally, the sizes of the boxes are calculated by taking length x width x height or depth. Length is the wider side of the boxes, width is the size measured from front to back of the boxes, and the height or depth is taken from the bottom to the top of the boxes.

Knowing about the measurement dimensions of boxes for different stylish boxes is important for numerous reasons. These include providing the benefit of making smart and effective decisions about the custom boxes to suit the best with your products.

Read this blog to know the measurements, their need, and the benefits of using them for your effective box packaging decisions.

What Are Sizes?

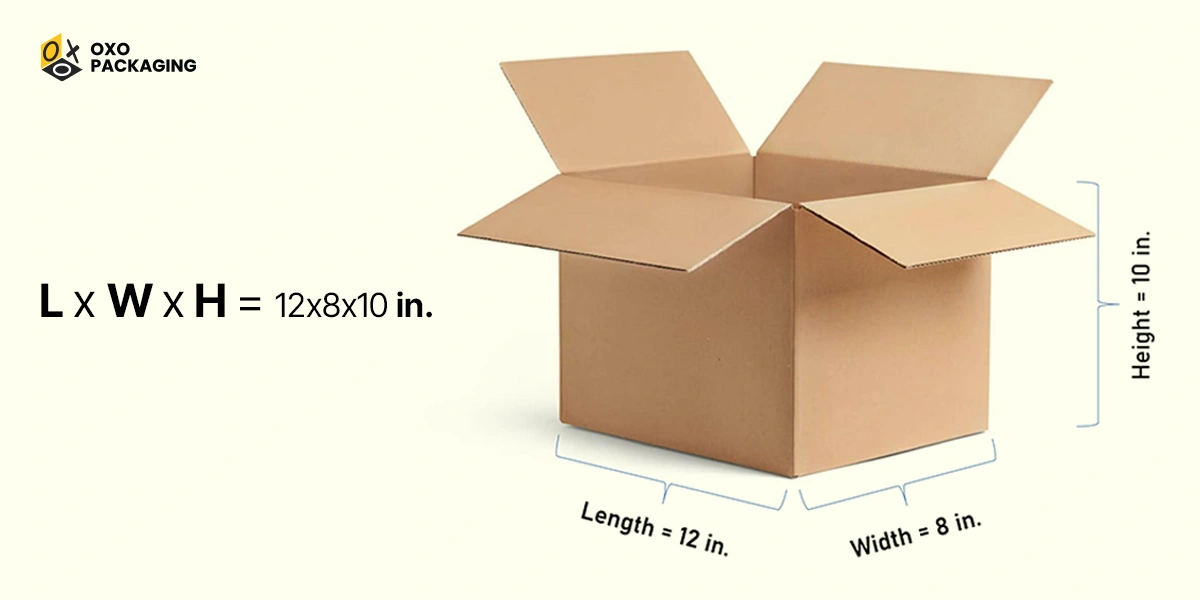

Deciding about the order of measurement dimensions of boxes is important to know in detail. This can be done by learning the basic information about the 3 dimensions of boxes. The formula for getting the measurement with the dimensions is length, width, and height. Let’s explore how to read product dimensions and understand them as follows:

-

Length

The length of the box is usually measured from the right to the left side of the boxes. It may or may not form the longest side of the boxes. Length is taken first in the measurement order.

-

Width

The width of the boxes is the shortest side of the boxes. This is generally measured from the front side to the back side of the boxes.

-

Height/Depth

The height of the box is measured, generally, from the bottom to the top of the boxes. Sometimes it is the longest side of the boxes. Many companies use depth in the replacement of height when calculating the dimensions of a box.

-

Gusset

Gusset is the extra space of the boxes, created to use this marginal space to increase the usable space without getting more space when these boxes are empty. This gusset space is kept intact till it is used to fill the space.

Want to know the size of a cereal box? Click here to learn all about cereal box height and dimensions

Importance of Getting to Know the 3 Sides of Boxes

Dimensions of boxes are highly important to know for various reasons. These provide many benefits in customizing box packaging to well fit the product in these boxes. Among the numerous benefits of these measurements, sizes, and exact dimensions can help you in the following ways:

-

Ease in Costing and Budgeting

Measuring the exact dimensions of the boxes supports you creating and designing the custom boxes. This will also help you calculate the exact costs and allocate budgets to organize your resources in the best possible way.

-

Measurement of Product Sizes

Crafting custom packaging can be made easy with the knowledge of the right dimensions of the box. This will help you personalize product packaging and support you to protect your products while transporting them to the destination.

-

Getting Customization Benefits

Right measurements of the 3 dimensions of boxes streamline your customization process with the exact product box sizes to exactly fit the content in these boxes.

-

Deciding the Perfect Size of Boxes

While you are getting the proper and exact measurements of your boxes, it is convenient to decide and customize the perfect sizes of your product boxes, including understanding the normal box weight to ensure the best fit for your packaging need

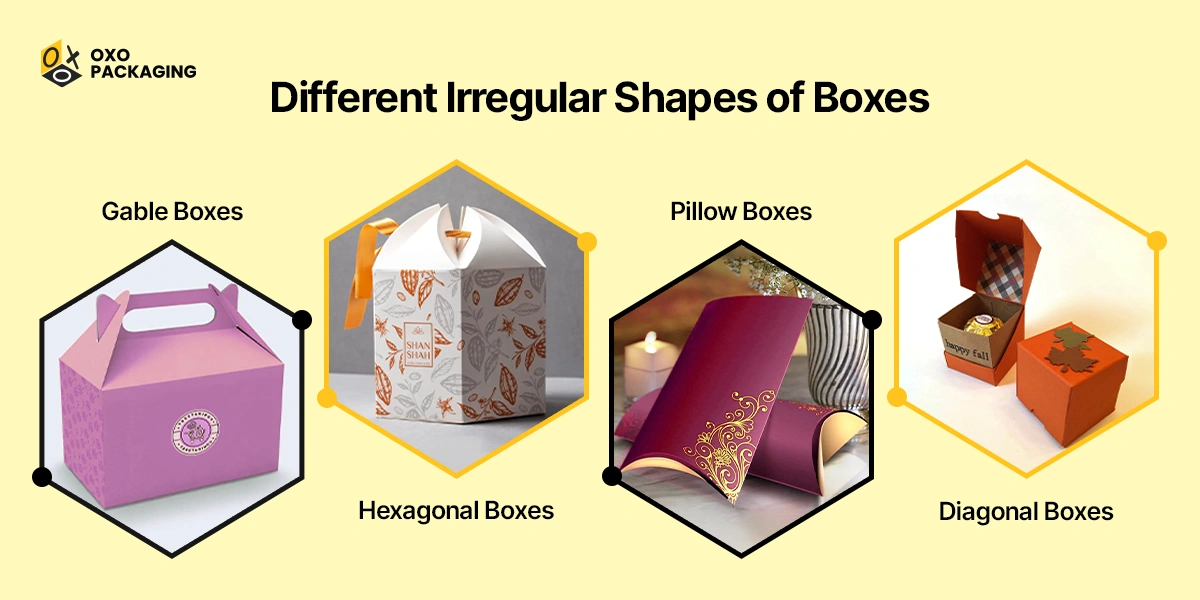

What are Shapes of Boxes?

There are many different shapes of boxes available to select according to the requirements of your products. You can create your product boxes with regular shapes of square, triangular, or round. There are still irregular shapes available on your product packaging with the right dimensions of the box you require. Undoubtedly, these require some different measurements for your boxes.

Examples of Different Irregular Shapes of Boxes

Besides regular shapes of boxes, you can consider irregular shapes to understand the measurements of the different boxes in shapes. Look at the following irregular shapes:

-

Gable Boxes

The measurement of gable boxes is similar to the regular shapes. However, we take the height from the bottom to the top of the gable boxes from the center of these boxes.

-

Hexagonal Boxes

Hexagonal boxes are measured in the same way as the regular boxes are. We take the length and height in the same manner; however, we get the width from one top edge to the opposite side of the top edge of these hexagonal boxes to get the final measurements.

-

Pillow Boxes

Pillow boxes are of irregular shape due to their different dimensions. These also have the same three dimensions. Yet the measurement of these boxes is a bit different from the regular shapes of boxes. The height of these boxes is measured from the center edges of these curved boxes to get the exact height of these boxes. Other things, like length and width, remain the same.

-

Diagonal Boxes

Diagonal boxes are similar to regular-shaped boxes with two parallel equal sides. Sometimes these boxes are measured with the dimensions height width depth order. Standard dimension order is followed by applying the same formula as Length X Width X Height.

How to Measure Internal vs External Box Dimensions?

Both internal and external measurements are important to customize the correct size of a box. You can measure the external dimensions by taking length, width, and height measurements first. Then apply the formula L x W x H to know the volume of the box externally.

For internal dimensions, you have to open the box to take the measurements. Take a measuring tape and start measuring length, width, and height in order, internally by taking the measurements from the inside of the box. Measure the thickness of the box when measuring internal dimensions.

Box Dimensions for Shipping

When it comes to shipping the products over long routes, different types of shipping boxes are used. You can choose the correct size for shipping box packaging according to your product needs, whether you want standard mailer boxes or large moving cartons. However, some common box dimensions for shipping retail products are 8 x 8 x 8 inches, 10 x 10 x 8 inches, 12 x 12 x 6 inches and 12 x 12 x 10 inches.

Standard Box Sizes for Different Industries

From food to cosmetics, different industries use different sizes of boxes that align with their product needs. However, some commonly used standard box sizes for different industries are as follows:

Small Mailer Boxes for cosmetics, jewelry, small electronics, and candles come in 2" x 2" x 4", 4" x 4" x 2" dimensions.

Medium Boxes for books, apparel, mugs, and multi-item kits come in 6" x 6" x 6", 12" x 9" x 4" dimensions.

Large boxes for sports goods, toys, shoes, and cookware have 18" x 14" x 12", 24" x 20" x 24" dimensions.

Common Mistakes When Measuring Boxes

Some common mistakes that can lead to poor box measurements are as follows:

- Confusion between height and depth when applying the formula.

- Neglecting to take the measurements of the box thickness.

- Ignoring the closing of the flaps when measuring a box.

- Relying on only internal measurements of the box.

Metric vs Imperial Box Measurements

The difference between metric vs imperial box measurements is the different units you use for measuring a box. Metric box measurements mean using units like millimeters, centimeters, and meters, while imperial measurements mean using inches and feet. Metric makes conversions simpler. However, imperial is a more traditional system.

What Order Are Dimensions for Your Boxes

Answering how to measure a box size, we follow this pattern, the box dimensions order is measured in the length in the first, the width in the second, and the height in the third step. Following a three-dimensional structure, product dimensions order is commonly used to indicate the measurement of specific objects, like packaging boxes.

Relationship of Sizes and Shapes of Boxes

The concept of measurement is meaningless without knowing the sizes and shapes of boxes of different kinds. After learning how to measure the dimensions of these boxes, it is better to know what relationship exists between the sizes and shapes of boxes. Sizes as discussed are the total area acquired of a box, while the shape is the structure of these boxes.

These may be in the form of any of the following:

- Squares Shape

- Trapezoid Shape

- Hexagonal Shape

- Rectangular Shape

Conclusion

Getting in touch with packaging experts can help you craft the exact size of your boxes in the best shapes and styles to exactly match your requirements. These boxes can be customized with different sizes and shapes as discussed earlier. This can help you with the perfect solution to smooth delivery of box packaging requirements.

The correct and standard order for box dimensions measurements is length x width x height (L x W x H).

A box for shipping can easily be measured by starting from the longest side of the box (length), then the shortest side (width), and then top-to-bottom measurements for height.

The core difference between internal and external box dimensions is that the external box dimensions give you the overall volume and size of a box. On the other hand, internal box dimensions refer to usable space inside the box packaging.

A gusset in a box refers to an extra piece of material added to the sides or bottom of a box. It increases the volume of the box and allows it to expand and stand upright when filled.

Knowing the correct box dimensions is important to ensure precision and product protection during shipping, handling, and storage.

The standard box sizes are as follows:

- Small boxes 8 x 8 x 8 inches

- Medium boxes 10 x 10 x 8 inches

- Large boxes 12 x 12 x 6 inches

Measuring irregularly shaped boxes is complex. Measure the maximum length, width, and height, including bulges. You may need to break the more complex-shaped boxes down into rectangular sections for volume calculations.

Metric measurements for the box dimensions are recommended due to their simple calculations and global standardization.