Mylar vs Rigid Packaging: Which One You Should Choose?

Choosing the right packaging has become important for businesses, especially for consumer-packaged goods (CPG) brands. As better Packaging can make or break your brand’s identity, it’s important to decide which packaging is right for your needs.

Mylar and rigid packaging are the most common packaging choices. But choosing one out of the two for your brand can get puzzling. We will explore mylar vs. rigid packaging in detail and help you determine which type suits your customer’s needs – read on till the end!

What is Mylar Packaging?

Mylar packaging has an interesting history. DuPont used the trademark Mylar® for the first time in 1952 for plastic film packaging. Over time, the term “mylar” became popular for flexible plastic in the packaging industry. It is a common term used for high-quality plastic flexible packaging (PET). PET simply refers to polyethylene terephthalate.

If your customers want lightweight, versatile, and durable packaging to keep products pristine, then Custom Shaped Mylar Bags are an appropriate option. Because it has a mixture of metal and plastic which keeps products fresh. This packaging has been built with harsh weather-resistant conditions protecting products against moisture, light, oxidation, and air.

Since you have now gotten an overview of what mylar packaging is about, you might be looking for further details to get a better know-how of this packaging type – keep reading.

Market Size of Mylar Packaging

Current packaging statistics show global mylar packaging market value will hit USD 26.1 billion by 2032. The study growth of market demand for this material shows that it is a go-to packaging option for businesses across all industries.

Manufacturing

Apart from market potential, another noticeable factor is understanding the manufacturing process which will help you determine the cost and packaging process of mylar packaging. The film of mylar packaging is prepared using PET resin. It is then stretched into a biaxial direction alongside two axes. Afterward, this film is combined with aluminum foil (low oxygen transmission rate) which exudes reflection.

In the next step, 200 degrees Fahrenheit temperature is applied to durable yet flexible sheets under high tension to make them smooth. Later on, the upper part is sealed with an effective heating system such as iron or hair straighteners.

Lastly, you can use different printing options tailored to customers’ demands to make mylar packaging eye-catching. A great variety of mylar boxes are popular among consumers – have a look at them.

4 Types of Mylar Packaging

There are many types of mylar packaging, but four common types are in demand as they can be used for a variety of purposes. Here is the breakdown of four common types:

- Custom Shaped Mylar Bags are suitable for grains, dried food, vegetables, spices, snacks, and coffee. They have a vacuum sealing system that doesn’t let oxygen and moisture enter.

- Flat bottom pouches are used for food and non-food items, including products such as tea, powders, pet foods, cleaning products, and seeds.

- Child-proof mylar bags are built with tear and puncture resistance. They keep sensitive products away from children and are commonly used to pack medicines, batteries, detergents, etc.

- Vista mylar bags are also stand-up and alluring pouches. Herbs, tea spices, dried flowers, and even precious metal, guns, and ammo are packed inside them.

Pros and Cons of Mylar Bags

Mylar packaging offers a lot of amazing benefits, but it doesn’t mean that it is a “perfect” packaging option. Here is a brief comparison of the pros and cons of mylar bags to help you decide if they are a good fit for your needs:

Pros

- Prevents Odor and Moisture: Mylar packaging has high barrier properties that keep products fresh. Its barrier ability also prevents odor from leaving the pouches

- Protects Children: Child-resistant mylars offer a special airtight closing mechanism that keeps children safe from opening sensitive items such as medicines, and detergents.

- Offers Recyclability: Mylar packaging materials follow ISO-certified packaging practices. They are recyclable and reusable which eco-aware consumers prefer to buy.

- Provides Longevity: This packaging increases the shelf life of products, especially edible ones for up to more than five years

Cons

- Mylars are expensive as they require a special heating system to effectively keep mylar packaging resistant to moisture, air, and light.

- Plastic used in mylars is neither sustainable nor environmentally friendly. This is why you should only consider biodegradable mylar bags which will be relatively expensive.

Uses of Mylar Packaging

From indoor to outdoor practices, mylar packaging has diverse applications in different walks of life. With its versatility, consumers are becoming more interested in mylar bags, and pouches. Here are the instances in which mylar packaging serve best in:

- Medical Emergencies: Mylar bags are versatile, lightweight, and durable. These characteristics make them perfect for carrying emergency essentials, as mylars can keep light and moisture outside to keep medicines safe from contamination.

- Outdoor activities: Zip-lock mylar bags are good to go for camping, hiking, and holiday vacations because they are waterproof, windproof, and tear resistant. You can make your trip and adventure memorable by keeping essentials safe against harsh weather conditions with mylars.

- Pet Food: Pet food items such as treats and specialty diets are challenging to keep fresh and moisture-free inside packaging. However, mylar bags provide protective properties to keep pet food usable for a long period.

- Gardening and Planting: Mylar bags keep garden seeds fresh and usable for a long time. They act as an effective material against air and moisture contamination to keep seeds and other gardening supplies unspoiled.

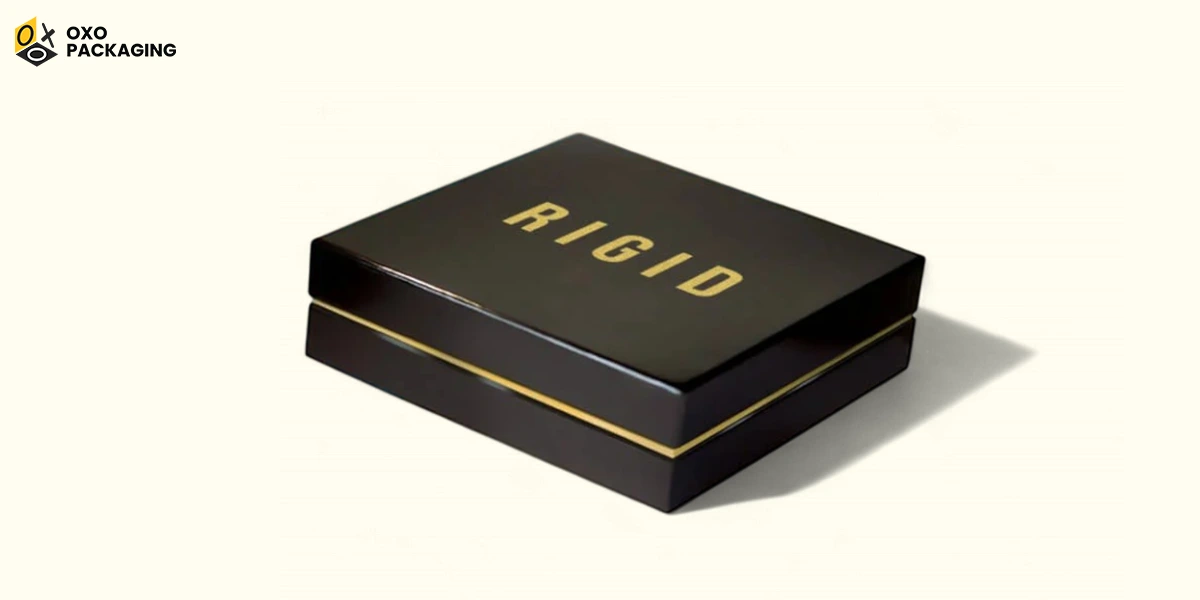

What is Rigid Packaging?

Rigid packaging consists of highly durable rigid materials such as plastic, paperboard, cardstock, and metals. Products packed inside rigid boxes cannot be deformed. Rigid packaging protects the product from bending, snapping, curving, or breaking, even if it is very fragile.

Durability of rigid packaging makes it desirable for delicate products and keeps them safe from knocks and bumps during transit. Luxury items and products that need protection during transit are most commonly packed inside rigid boxes.

This packaging will be a better option for those businesses who prefer both high-quality material and attractive packaging.

Market Size

There has been a rising demand for rigid packaging among consumers. It is evident from recent studies that the global rigid packaging market will likely hit USD 704.24 billion by 2032. With these numbers, it’s clear to see that brands prefer rigid packaging over the other available options.

Manufacturing Process

As there are several types of materials used for rigid packaging, the manufacturing processes are different for each material. Here is a brief overview of rigid packaging made from paperboard and cardboard as it’s the most common rigid packaging you’ll come across:

Rigid boxes have an inner base of a 2-3mm thick paperboard and an upper lid wrapped with specialty paper. Cutting dies are used to cut paperboard to customize its size and shape. Afterward, scoring dies are used for folding to create a basic inner structure.

Then, the lid paper is trimmed to the size of the inside paperboard. Later on, the paperboard and lid are joined together through gluing. Once this basic structure is prepared, it goes through fine printing, texture, and finish to give the rigid box a luxury feel.

4 Types of Rigid Packaging

Although there are many types of rigid packaging available, the three common types are mostly used by businesses. Here is a short overview of three types of rigid boxes that businesses rely on:

- Cardboard rigid boxes are made from cardstock and can be customized easily.

- Hard plastic rigid boxes are used to pack high-end products.

- Metallic rigid packaging is suitable for packaging items that need utmost protection.

- Glass rigid packaging is best suited for liquids such as medicines and perfumes.

Pros and Cons of Rigid Packaging

Just like mylar packaging, rigid packaging also has its pros and cons. Let’s explore both:

Pros

- This packaging provides sheer strength for fragile items and ensures that products don’t get damaged during the transit process.

- It gives an elegant visual appearance to products and provides a great unboxing experience to the customers.

- Plastic rigid packaging preserves food flavors and ensures that food items don’t get contaminated with dust and bacteria.

- Rigid packaging is made from recyclable materials such as glass and hard plastics, ensuring that it provides more sustainability.

Cons

- Rigid packaging is costly compared to options such as mylar because it is made from highly durable materials that are expensive to make.

- Shipping charges of rigid packaging are higher because this packaging is heavier in weight and increases the overall freight costs.

Uses of Rigid Packaging

Different types of rigid boxes are used across different industries each serving a unique purpose. You can consider each one to assess which rigid packaging material is appropriate for your customers.

- Food and Beverage: Glass jars, glass bottles, metal cans, and plastic containers preserve food flavor and ensure freshness for a relatively long period. This is why rigid packaging is a suitable option for many high-end food brands.

- Cosmetic and Skincare Products: Hexagonal-shaped cardboard secures sensitive formulations of cosmetic and personal care items. Also, it has premium luxury packaging on its upper lid that strengthens your brand positioning.

- Electronics: Rigid containers are very suitable for electronic appliances due to the polyurethane foam used inside them. They have high-quality insulating properties that prevent damage and ensure that electronic products don’t catch fire.

- Health industry: Rigid cardstock contains no harmful materials and is suitable for packaging sensitive medications. This material also has a high shelf life, which allows medicines to be stored for a long time.

Common Styles Used by Most of the Brands

When it comes to choosing styles of rigid boxes or mylar bags, many brands opt for these common designs. Consider these designs to highlight your brand for your potential customers:

Popular Styles of Rigid Boxes

- Rigid Shoulder: Highlight your brand with exposed neck and two shoulders style.

- Magnetic Opening: Make a luxury feel with elegant unboxing magnetic mechanism.

- Rigid Foldable: Ensure convenient opening and closing experience to your customers.

- Open Door: Let your customers enjoy joyful unboxing experience with open door boxes.

- Slide-Drawer: Offer convenience and memorable packaging with sliding mechanism.

- Two-Piece: Exude a premium and luxurious feel of your high-end products.

- Turned Edge: Provides robust protection for the product during shipping and storage.

- Clamshell: Prevent crushing and damage to inside-packed contents with clamshell boxes.

Popular Styles of Mylar Bags

- Pillow Shaped: Provide a compact and visually appealing packing for snacks and chips etc.

- Window: Allow your customers to examine the inside contents without opening mylar bags.

- Die-Cut: Enhance the perceived value of your product's presentation with die-cut style.

- Stand Up: Catch immediate attention of customers owing to upright stand on shelves.

- Child-Resistant: Prevent access of sensitive packed products like medicines from children.

- Resealable Pouches: Lock in freshness, quality, flavor, and aroma with resealable bags.

- Custom Circle Bags: Highlight your brand and boost shelf appeal with unique circle shape.

- Squeeze Pouches: Allow customers to extract required amount through convenient squeezing.

Comparisons of Rigid vs Mylar Packaging

|

Aspect |

Mylar Packaging |

Rigid Packaging |

|

Structure Type |

Flexible structure to bend the shape and style easily for pouches, bags, or wraps |

Retain the shape and style and don’t bend; like glass, metal, and boxes |

|

Materials Type |

Made from plastic (polyethylene or polypropylene), aluminum foil, paperboard, or wax paper |

Made from rigid materials including glass, metal, and rigid plastics such as PET or HDPE |

|

Versatility |

Provide great versatility, in design and usage, including pouches, bags, films, and wraps |

Offer less versatility in design while retaining shapes like boxes, metals, glass, jars, and bottles |

|

Applicability |

Hold gently and protectively snacks, beverages, frozen foods, and lightweight items |

Offer superior protection for fragile items and heavy-duty items like perfumes |

|

Barrier Properties |

Aluminum foiling protect items from light, moisture, oxygen, and moisture |

Offer limited barrier properties compared to mylar bags against harsh environmental factors |

|

Weight |

Lightweight to packaging materials |

Heavyweight due to usage of heavy duty packaging materials |

Common Styles Used by Most of the Brands

When it comes to choosing styles of rigid boxes or mylar bags, many brands opt for these common designs. Consider these designs to highlight your brand for your potential customers:

Popular Styles of Rigid Boxes

- Rigid Shoulder: Highlight your brand with exposed neck and two shoulders style.

- Magnetic Opening: Make a luxury feel with elegant unboxing magnetic mechanism.

- Rigid Foldable: Ensure convenient opening and closing experience to your customers.

Popular Styles of Mylar Bags

- Pillow Shaped: Provide a compact and visually appealing packing for snacks and chips etc.

- Window: Allow your customers to examine the inside contents without opening mylar bags.

- Die-Cut: Enhance the perceived value of your product's presentation with die-cut style.

Comparisons of Rigid vs Mylar Packaging

We will draw a parallel comparison of rigid vs mylar packaging. It will help you understand which packaging will be suitable for your consumers.

Cost

In terms of cost, rigid packaging will be more expensive due to its high-quality materials than mylar packaging. For example, a small rigid box might cost $1-5 dollars while mylar boxes might only cost a few cents.

Strength and Durability

When it comes to durability, rigid packaging wins as it provides superior protection. However, mylar bags cannot be used for shipping products. The biggest reason why brands use mylar packaging is that it keeps items safe from moisture.

Environmental Factors

Rigid packaging and mylar packaging materials are both recyclable. But in comparison, rigid boxes are more environmentally friendly because paperboard and cardboard are biodegradable. However, plastic packaging in mylar bags can only be recycled, which is not a very ideal scenario for sustainability.

Consumer Preferences

If your customer is more interested in luxury and sturdy boxes, then rigid boxes will be befitting for them. But if consumers want fresh and unspoiled products for short and long-term use, mylar bags serve better.

Styles and Designs

Customers demand diverse styles and designs based on their choices. In this matter, you need a packaging type that is more flexible to customize and tailored to your customer’s choice. Mylar packaging is relatively easy to customize in style and design due to its highly flexible plastic material rather than rigid cardboard.

Which Type of Packaging Should You Prefer?

We have discussed and compared rigid vs mylar packaging in detail. Each one is unique and offers specific benefits. In case you are pondering which one will perform better for your consumer, you will need to weigh the benefits as there is no one-size-fits-all packaging solution.

If you still need help to assess more appropriate packaging solutions for your consumers, contact us today to get the answers to your questions. We can also provide you a free packaging quote to help you decide the packaging that is best suited for your needs!