What Is A Corrugated Box? An Ultimate Guide

It is true that many businesses rely on corrugated packaging, from simple retail boxes to transporting goods. Therefore, the global market of corrugated boxes is expected to expand at a CAGR of 3.0% by 2032.

A corrugated box is an unsung hero in the packaging industry. Let's start this debate based on facts. This material can be recycled up to 25 times. Many businesses actively use corrugated boxes for shipping in the US. 80% of the shipments are generated from corrugator plants.

The first thing you need to know is that corrugated and cardboard boxes are not the same. While discovering the numerous things about corrugated boxes to run your small or large business with effective shipping needs. Mistakenly, they are misused together.

Read this article to learn more about corrugated boxes, how they are different from cardboard, and their types. Let’s get started!

What are Corrugated Boxes?

Corrugated refers to the fiberboard container made of paper pulp and combined with two layers of sheet and ruffle sheet inside. When we define corrugated, it implies a fiberboard made from packaging sheets with durability and flexibility. The term corrugated means a material composed of three sheets of board where the outer sheets are flat liner and sandwiched between, known as rippled.

90% of all products shipped in corrugated boxes in North America indicate the dominant usage of this material. You can use these boxes for retail purposes, shipping, mailing, product display, and more. Having various applications, this becomes a more reliable choice for shipping and transporting goods. You can adjust its thickness to increase product protection. With these thicknesses, they can absorb shock or vibration and use less cushioning, which helps you reduce shipping costs.

If you ship on a daily basis, then figure out the difference between cardboard and corrugated boxes to use the right type of material for your business. Let’s read the difference here!

Corrugated vs Cardboard Packaging

Cardboard is a thin or pasteboard material used for packaging products. They are lightweight, sturdy, and used to protect products on the shelves.

Whereas corrugated is thick, fiberboard is used to protect products during shipping.

Still not get the enough difference? Go through this table and learn the detailed difference between cardboard and corrugated boxes for your business packaging:

Corrugated Vs Non-Corrugated Boxes

The difference between corrugated and non-corrugated boxes lies in the construction, where corrugated boxes use a three-layer, fluted, and linerboard construction, which offers superior strength and shipping properties. Non-corrugated boxes consist of a single layer of thinner materials, which is ideal for lightweight shipping. While non-corrugated boxes may not provide superior protection, if we consider branding for small items, non-corrugated packaging should be your choice.

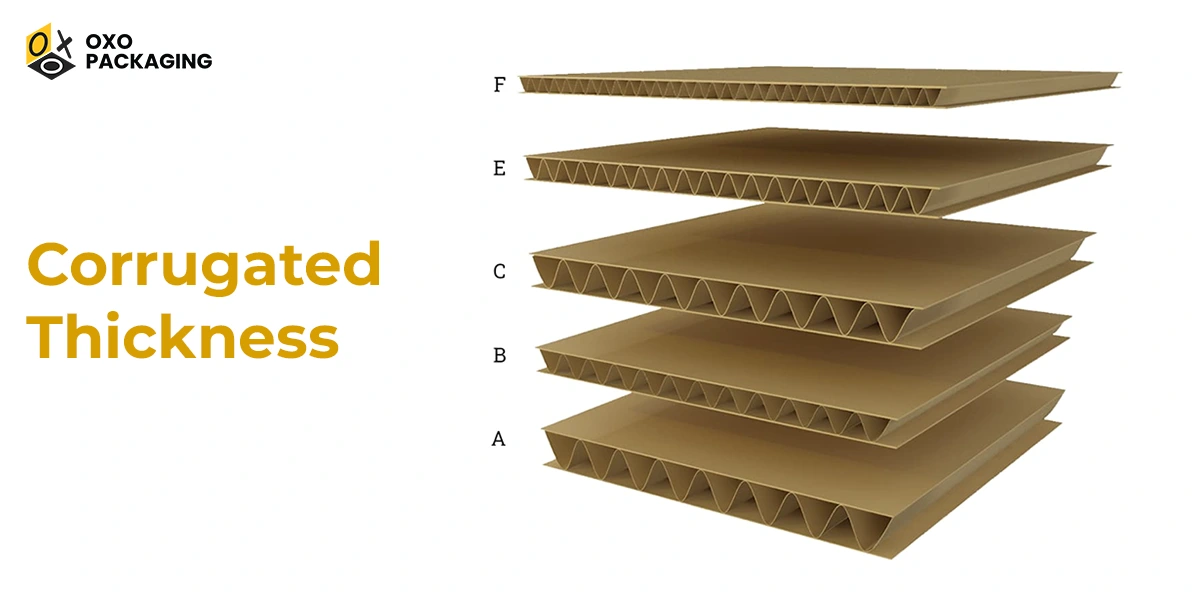

Corrugated Flute Types (Corrugated Thickness)

The flutes–typically known as the ruffled layer between the linerboard–are used to increase the corrugated thickness. These create a space between layers and act like cushioning to provide additional product protection from damage.

The corrugated flute comes in different thicknesses and has unique categories:

- A-Flute-¼ thick: used to protect fragile items during shipping as they are the largest size of flute.

- B-Flute-? thick: and are less thicker than A or C but are great tear or puncture resistant.

- C-Flute-3/16 thick: used to ship dairy products, glass products, or furniture.

- E-Flute-1/16 thick: used in packaging normally for mailer boxes.

- F-Flute-1/32 thick: used in packaging such as, shoe, cosmetics, perfumes, and jewelry boxes.

Types of Corrugated Boxes

Liners (creased paperboard sheets) and fluting together with adhesive glue, create the structures of corrugated boxes with different thicknesses. Now with different layers of these liners and flying decide its thickness and define the different types of corrugated. Below are these types in detail:

Linerboard – A flat sheet with two layers of paper and fiber. One layer consists of paper and recycled fiber.

Single Face – A flat sheet of linerboard combined with a single flute on one side.

Single Wall – Typically, two sheets of linerboards with one fluted fiberboard (ruffles sheets) glued in between.

Double Wall – Combine three sheets of linerboard and two flute fiberboard with glue simultaneously to create thickness.

Triple Wall – Glued four-liner board sheets with three fluted fiberboards in between.

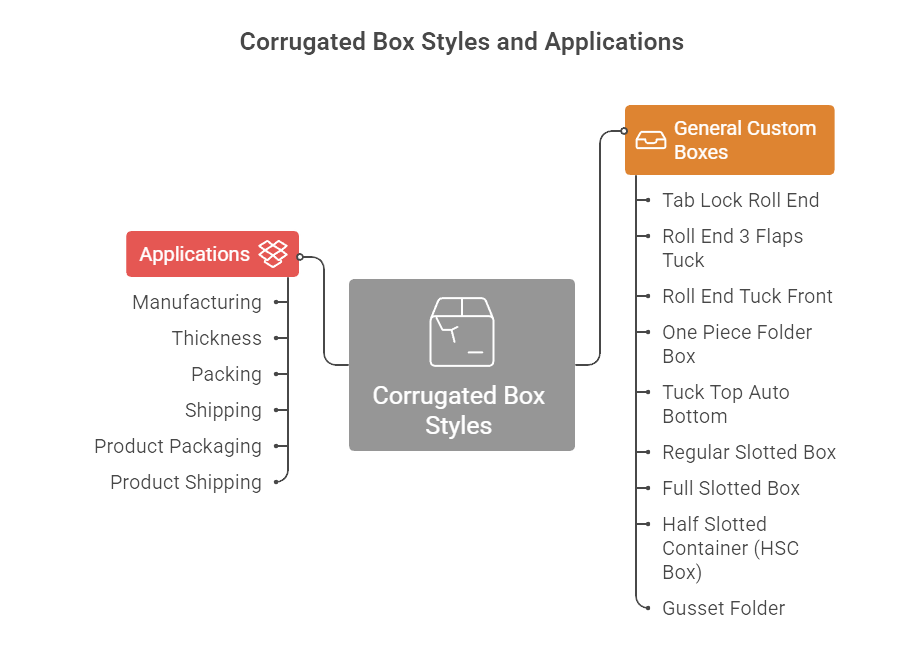

Corrugated Box Styles

Regarding packaging, the corrugated flute-F is used for storing multiple products in various styles, from manufacturing to thickness and packing to shipping corrugated boxes covering all solutions. With the right dimensions and measuring, different corrugated box sizes can be created for product packaging and shipping. The corrugated shipping boxes are more sturdy and durable for protecting goods during transit.

The majority of the corrugated box style falls under the categories of the general custom boxes:

- Tab Lock Roll End

- Roll End 3 Flaps Tuck

- Roll End Tuck Front

- One Piece Folder Box

- Tuck Top Auto Bottom

- Regular Slotted Box

- Full Slotted Box

- Half Slotted Container (HSC Box)

- Gusset Folder

To get your desired corrugated box style; contact us and let your vision come into reality.

Industry Uses of Corrugated Boxes

The uses of corrugated boxes are versatile and popular in various industries, whether for protection, branding, or cost saving. Almost every industry considers corrugated boxes for their packaging. Here are some of the common uses of corrugated boxes, which you should know:

Food & Beverage Industry

Corrugated boxes are extensively used in the food industry due to several storage, shipping, and health benefits. These boxes effectively maintain beverages, and food like pizza, sandwiches, and others with its specialized coating that manages moisture and preserves the food quality during storage and in shipping.

E-Commerce & Shipping

The most common use of corrugated boxes is transporting goods safely from one place to another, ranging from small retail boxes to large and heavy appliances. Due to their heavy cushioning, crushing, and puncture-resistant properties, they are the unsung hero of shipping and the e-commerce market.

Retail

Corrugated boxes are also used for display and branding of various items, due to the customization that allows business owners to create their brand image through designs, colors, and premium finishes.

Moving & Storage

When moving and storing supplies and furniture, a primary concern is the potential damage during transit or while in storage. Corrugated boxes eliminate external damage and address these issues by providing immense strength and a cushioning effect for your products.

Textile Industry

Due to online shopping, the demand for corrugated boxes risen as brands opt for boxes that both protect and present their textiles. To protect fragile items during shipping, you can also use air flot boxes made from corrugated cardboard, which is an affordable packaging solution, ensures intact delivery, and is cost-effective for shipping.

Conclusion

Corrugated packaging material is considered to be versatile due to its numerous benefits. Are you running a small or large business and looking for packaging or shipping needs? Read this article and get to know about corrugated boxes for your packaging solutions. These boxes are sturdy and durable and used for shipping or storing your goods.

Whether you are looking for retail or transporting products, considering corrugated boxes with all customization benefits can save you a lot of costs. Pay attention to its features, structures, types, style, and sustainability in this article and get a better idea for your packaging.

Still confused? Don't worry, we will help you find the best corrugated solution for your business needs.

A corrugated cardboard box is a durable, lightweight shipping container made from a three-layered, fluted material: a central, wavy "fluting" sheet sandwiched between two flat outer liners

A corrugated shipping box is designed for strength, shock absorption, and stacking. These boxes are industry standards for shipping, protecting fragile or heavy items during transit.

Heavy-duty corrugated boxes, such as double-wall and triple-wall boxes, are designed for superior strength, stacking stability, and protection of heavy or fragile items.

Corrugated boxes are primarily used for shipping, storing, and protecting goods during transit, offering a lightweight yet strong solution for industries like e-commerce, retail, and manufacturing.

The primary difference between a cardboard box and a corrugated box lies in their structure and strength: corrugated boxes consist of three layers, designed for heavy-duty shipping and durability, while cardboard boxes are single-layered, thinner, and meant for lightweight, retail packaging