Your Guide to Understanding the Essentials of Foil Stamping

Introduction

Choosing the printing option that is best suited to the requirements is an important question for every business owner. Among many solutions, foil stamping is one of the best stamping/printing and packaging solutions in today’s ever-changing and diversified packaging industry. It compromises printing, stamping, and packaging solutions.

It is a better option to consider because it has features of durability, cost-effectiveness, and eco-friendliness. If you want to know what foil stamping is, you are at the right place. Read on to find nearly everything you need to know about this stamping technique!

So let’s dive in,

What is Foil Stamping Used for?

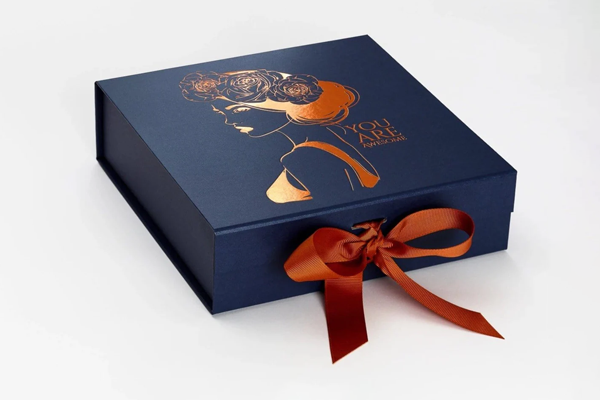

Before we explore types and methods to apply foil stamping, let’s explore what foil stamping is used for. This type of finishing is primarily used on business cards and product packaging to get the attention of prospects. Such stamping options not only add a reflective touch with metallized appeal but also offer an embossed feel.

You can pick from silver as well as gold foil according to your preferences. By blending these metallic foils with different colors, you can create personalized foils that resonate with your brand’s theme.

Types of Foil Stamping

Foil stamping is a popular type of stamping/printing, and there are many types. You can consider some of the following examples to understand this strategy to a great extent:

Metallized Foil

Metalized foil stamping is second to none when it comes to quality and finish. Gold and silver are the most popular types of stamping used for packaging solutions. This stamping enriches the printing of products in a multitude of colors.

Pigment Foil

Pigment hot stamping foils are used mostly in flat, non-metallic colors. This stamping is widely used on plastic and paper. Pigment foil stamping is available in a variety of colors and shades as well.

Pearl Foil

Pearl foil provides a translucent ‘Pearlescent’ sheen to your products. This type of foil stamping printing is widely used to enhance the look of the product packaging. It is one of the most charming and attention-grabbing types of printing.

Effects Foil

Metallic effect foil stamping is available in multiple colors and styles. It can be printed in different patterns. This foil effect can show an attractive look in multiple design options. It is processed with a thin metal layer.

Holographic Foil

Holographic foil is processed as an embossed pattern. It shows a variety of shades when viewed from different angles, though it is processed in the same way as the metallic foil. Holographic foil is more often used in gold, silver, and other metal colors. The holographic foil printing is made with a stamping machine.

After the application of heat, this foil stamping becomes permanent. This feature of holographic foil printing makes it eye-catching for holographic rigid product packaging and hence increases sales.

Scratch-Off Foil

Unlike other foil stamping, scratch-off printing is easily removable from the surface on which it is printed. The main objective of this printing is to hide some important information that can be recovered after scratching or peeling the foil stamping from the surface.

Scratch-off stamping can be printed on many materials like paper, cardboard, UV-coated paper, PVC, and ABS materials. It is commonly used for printing scratch-off cards. Debit cards are an example of scratch-off cards as they contain some information that can be found after scratching.

See Also: Importance of UV Coating in Printing and its Drawbacks

Foil Stamping Types Based on Substrates

When it comes to substrates used for foil stamping, endless options are available. Here are a few foil stamping types based on the substrate you pick:

- Vertical Foil Stamping: This type of foil stamping is applied on flat and cylindrical substrates.

- Flat Foil Stamping: This method adds a relatively raised foil on substrates.

- Peripheral Foil Stamping: In this type of foil stamping, foils are transferred on the outer regions of the substrates.

Techniques of Foil Stamping

There are two major techniques or processes for foil stamping. One is an older technique called “traditional foil stamping,” and the other is named “digital foil stamping.” Both can give the same result in many cases. However, both are different techniques with their pros and cons.

Traditional Foil Stamping

Hot foil stamping machines are used for digital stamping. These machines provide a less shiny finish compared to digital stamping. In traditional foil stamping, dies of customized plates are used to press into the materials required for stamping. Traditional stamping needs to have many dies and/or customized plates to stamp by pressing it onto the paper or other material.

This method of processing requires more human effort and involvement, which is why this method of foil stamping is expensive.

Digital Foil Stamping

Digital foil stamping is the latest and improved foil stamping process. This method has largely reduced human efforts, time, and cost, which leads to more precise results in printing and ensures quality printing of small elements that have sharp edges.

The digital foil stamping process is also cost-effective. This technique increases the accuracy and does not require the use of several dies for printing small elements. Using this technique has largely reduced the dependency on the dies and metallic plates.

Cost of Foil Stamping

It is one of the most affordable options to gain the attention of your customers. This method of printing is very cost-effective as compared to the result this type of printing produces but not that much cheaper as compared to offset printing . Before moving forward, it is very important to know the following key points that determine the cost of foil stamping:

Artwork Cost

Before going into the details of Printing and packaging, you must consider the artwork cost of your design. It includes the design colors, their shades, and different other elements.

Costs of Materials

Material is the prime element in deciding the cost of foil stamping. Major costs are charged on dies and plates for the design elements. The more the design elements, the more of the dies and plates are required. Digital Stamping overcomes costs up to a great extent because it does not require dies and plates to print the product.

The other factor of cost consideration is the type of material that is used for this stamping. For example, holographic stamping is a bit costly compared to other procedures.

Labor Costs

Foil stamping with traditional techniques requires extensive labor work and time for printing, which contributes to a major portion of the cost of printing and the total cost of the product, whereas digital techniques require less cost of labor.

Styling of Foil Stamping

Among all the printing and stamping processes, foil stamping is one of the best methods of printing products. It gives the products a stylish look that no other type of printing process can give. This type of printing has many forms, such as glossy, matte, gold, embossed, etc. It not only makes products attractive but also distinguishes the value of the brand from the competitors.

Sustainability of Foil Stamping

Hot foil stamping is considered environmentally friendly. The hot metallic process of printing uses less energy. The layer of this stamping is so thin that it is harmless for the recycling of material like paper. And no adhesive is used in this technique as well.

Due to these reasons, foil stamping doesn’t affect the quality of recyclable materials. The paper on which the hot foil is printed can be recycled without any difficulty. The stamped printing solution is sustainable as compared to the other printing options.

Limitations of Foil Stamping

Foil stamping is undoubtedly one of the best printing solutions for many reasons. However, like all other printing solutions, this process also has some of its limitations. If we’re talking about the Traditional Foil Stamping, it doesn’t fit well in the case of small elements and tiny letters. Traditional Stamping requires dies and plates depending on the number of design elements to print.

For example, with hot foil, the pressure may vary and result in weaker printing. Some of the major issues with traditional techniques have already been resolved by Digital Stamping. A simple printing machine is used for this type of stamping that is easily operated with a computer, reducing costs and saving time as a result.

Durability of Foil Stamping

Along with other features, foil stamping printing solutions are also durable. Boxes that have this stamping stay safe even if they get scratched. This type of printing doesn’t get damaged by the mishandling of the products. That is why it is also convenient during shipping without losing the printing quality. It is usually resistant to moisture as well.

Other Types of Packaging Finishes You Must Know

Endless types of finishes are available other than foil stamping. You can explore and benefit from exclusive facilities that enhance your packaging and other printed objects. Some exceptional options you can find out there are embossing, debossing, and spot UV coating. All these finishes are famous for their premium feel.

You can also explore options like gloss coating and matte lamination to protect your packaging and cards at an affordable price.

Where to Get Custom Foil Stamping Services?

Now that we know nearly everything about foil stamping, let’s explore where you can get these services for your packaging business cards, and more. Opting for a reliable service provider is essential to get quality facilities in this regard. You can partner with a reliable online vendor like OXO Packaging to avail foil stamping services.

By partnering with us, you can enjoy endless benefits like free design support for your packaging and cards, quality finishes, and exceptional prints. You can also expect fast turnaround, enjoy free shipping, and admire excellent customer service.

Conclusion

Considering all of the benefits, foil stamping is highly recommendable for enhancing your brand’s image. It is undoubtedly the best printing and packaging technique to help you stand out in today’s age of high competition. Get in touch with OXO Packaging today to discuss your packaging needs, and we will provide you with the best packaging solutions that will improve your sales.!