A Simple Guide to Learn Cost Factors in Manufacturing Rigid Boxes

Rigid boxes are second to none in presenting the luxury products of your brand. These boxes are ideal to enhance your products' perceived value, your brand image, and the unboxing experience. However, rigid boxes are among the high-cost packaging produced with top-notch packaging materials and allied facilities.

Read this blog to learn factors that determine the overall cost of rigid boxes, and also how to save cost of rigid boxes to an ideal level.

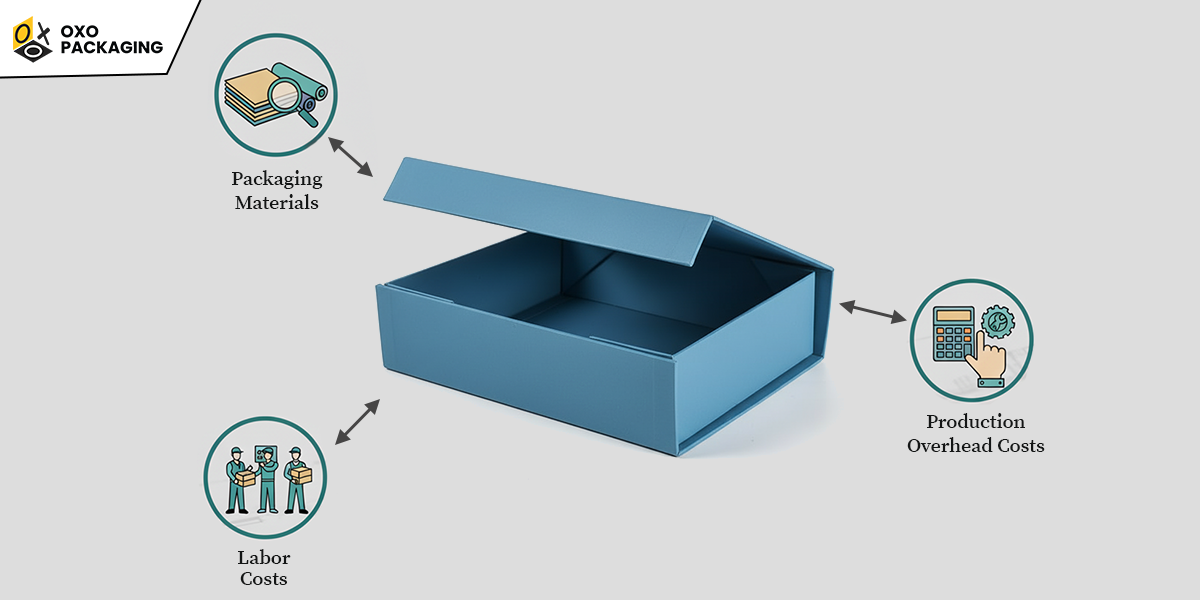

Cost Factors in Manufacturing Rigid Boxes

A rigid box is produced with thick, sturdy, and durable packaging materials that form the first and foremost important factor of the cost of a rigid box. Materials, though the first important factor, yet other factors are still to be considered to determine cost, control it, and produce cost-effective rigid boxes for your brand.

Consider the following significant factors to understand, realize, and reduce your cost of rigid box packaging for your brand:

-

Packaging Materials

Luxury and premium packaging materials are a basic and fundamental cost factor of rigid boxes. These materials are of higher quality, durable, and thick. The cost is still not finalized; it needs more raw materials to produce high-quality rigid boxes. Wastage is another big factor that is essential for rigid box luxury packaging.

-

Labor Costs

Materials once arranged need to be processed to convert them into a finished form of rigid boxes. The labor applied to produce rigid boxes can cause a higher cost of rigid boxes. This is due to the specialized skills, time, and other cost factors to produce rigid boxes. Complex designs, multiple finishes, and setup costs contribute a major chunk to boosting the costs of rigid boxes, especially when produced in small runs.

-

Production Overhead Costs

One of the major cost factors in manufacturing rigid boxes is the manufacturing overhead. This includes each and every expense that is incurred to produce rigid boxes, excluding direct materials and labor. All other costs are indirectly applied to produce these boxes in the end. The major elements that contribute a major role in boosting the cost of overheads include customization in shapes, sizes, and styles.

6 Major Industries Using Rigid Boxes for Their Products

Rigid boxes are a fundamental choice for different premium brands and businesses to meet their custom packaging requirements. Here is the list of 6 major industries using rigid boxes for their brands:

- Jewelry Businesses

- Fashion and Apparel

- Gift Industry

- Electronics

- Cosmetics

- Food and Beverages

How to Save Money

Rigid boxes, though, are the premium packaging solutions that require more costs and expenses to produce. Materials, labor, and overheads all these factors are all costly and cannot be avoided. Still, you have an opportunity to reduce and control your cost of producing rigid boxes, storage, handling, and shipping costs.

Here is how you can reduce your costs with the rigid boxes of your brand:

-

Optimize Materials and Sizes

Choose high-end materials that do not require any extra tooling cost to reduce the sizes, thickness, and other specifications to meet your custom requirements. Produce rigid boxes with the ideal shape, size, and style to meet your product packaging requirements. This will, in the end, reduce your cost by controlling the wastage of materials.

Produce exact dimensions of your rigid boxes with cost-effective liners instead of finding and applying decorative premium materials. Consider different options to match your perfect luxury packaging needs without paying extra for your rigid box packaging.

-

Streamline Design and Production

Choose a minimalist design with fewer color options that help you reduce your cost of rigid boxes without compromising the quality of your product packaging. A great example of minimalist design is Apple; you can consider getting an idea for your brand. This type of rigid box, with the use of standard templates, can help you avoid different extra costs, like mold costs for your rigid boxes.

-

Order Strategically

Bulk size purchase orders help you gain bulk discounts on one hand, and an increased storage cost on the other. You need to calculate the exact size of your materials packaging requirements and other allied products to use to manufacture your rigid boxes. Economic Order Quantity (EOQ) is the best solution to calculate the cost-effective order quantity of your brand.

Also consider other packaging materials and club them to order in bulk and save big with economies of scale.

-

Consider Alternatives

The world is full of choices and alternatives, similar is the case with packaging materials. You might explore, choose, and use the best alternatives without compromising on the quality of your rigid box packaging. These might also help your brand save a lot of your rigid box packaging and provide the premium outlook and great protection of your luxury products.

Conclusion

A lot more options are available to consider to save costs for your brand during handling, storage, and shipment. Create stylish, rigid boxes with standard shapes, sizes, and other specifications with a minimalist design. This helps you reduce your cost, save your resources, and the great thing is not to compromise on the quality of the premium packaging of your brand.

Otherwise, you might end up paying larger expenses on shipment, transportation, and storage of your rigid box packaging.

The cost of a box can vary a lot depending on various factors. Rigid boxes are among premium packaging choices and are produced with high-end materials, the cost of which varies from 0.5 $ to over 10 $ per piece. Materials, labor, and a lot of other factors are important to produce these boxes, and they differ in quantity and price to produce rigid boxes.

Many factors, like materials, labor, printing, finishing, and other additional costs, collectively form the whole cost of a rigid box. You can calculate the cost of a box by collecting materials, labor, and overhead costs, and dividing the outcome by the produced boxes to exactly determine the cost of a rigid box.

OXO Packaging, a specialized custom packaging solution in the USA, can boost your brand identity, image, and value with personalized rigid boxes. Contact us and share your custom rigid box packaging requirements. And get ready to receive your personalized rigid boxes at your business place without paying a single penny on account of shipping costs.