Length Width Height Dimensions: A Comprehensive Review

Imagine your premium product gets ruined due to oversized packaging, or worse, the packaging is so tight that your delicate item gets damaged or stuck in boxes. That’s why, before ordering your packaging boxes, it is essential to learn the dimensions of boxes, which are width, length, and height. Additionally, gain insights into the fate of your boxes, shipping costs, space utilization, and product protection that revolves around dimensions!

Importance of Dimensions

Always keep in mind that packaging is the shield of your product, and minor errors like oversized or tight boxes will affect the whole packaging game. The importance of dimensions can’t be overstated when it comes to determining the shapes and sizes of objects. Here are some important roles played by height, length, and width in your product packaging:

Product Protection: A correctly sized box ensures there is no space inside the volume of the box, preventing items from shifting around during shipping and handling. This will significantly help in reducing the risk of damage and ensure that your product arrives safely and in good condition at the customer's doorstep, a Plus Point in the customer’s diary.

Cost Efficiency: Another significant effect the dimension has is on shipping costs. Some famous shipping carriers use pricing techniques called dimensional weight(DIM weight), where charges are based on the volume the package occupies in the carrier’s vehicle, not just its actual weight. That’s why making your boxes accurately according to the needed dimensions and vertically can save shipping costs.

Storage Optimization: Knowing the precise external and internal dimensions ensures more efficient stacking and maximizes available space in warehouses, on pallets, and in delivery trucks.

What are Length, Width, and Height?

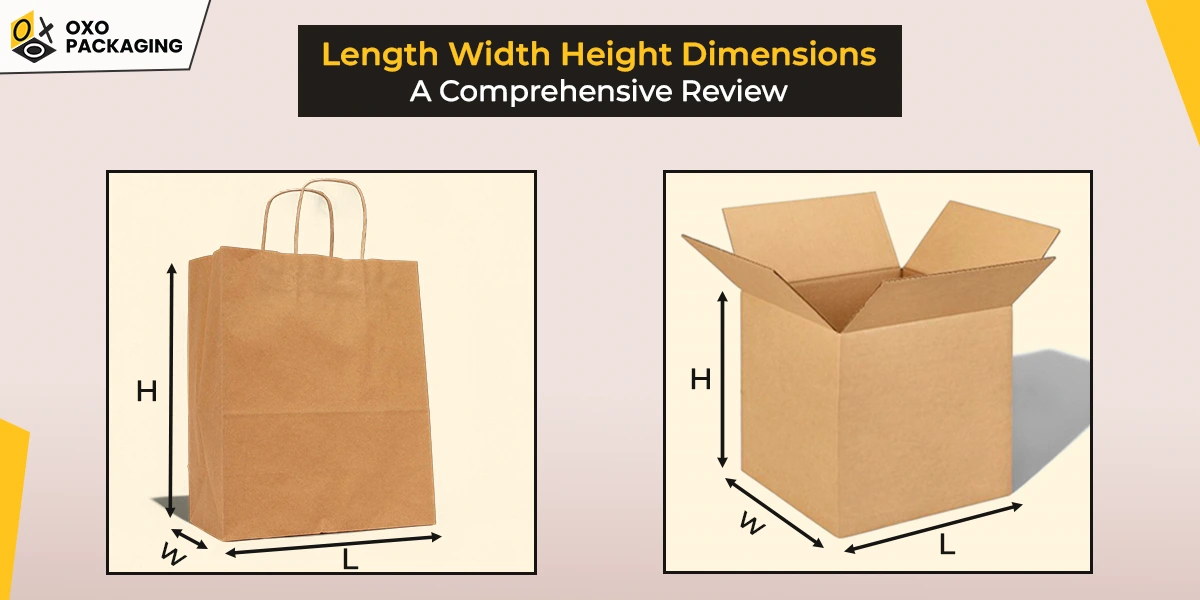

The Length x Width x Height formula calculates the cubic size of every physical object. However, the length, width, and height formula is commonly used to measure the dimensions of boxes and bags. It is an important part of custom packaging.Before measuring the dimensions of a box, let’s look at what length, width, and height are:

Length: The longest side of the product or box base is measured to determine the length.

Width: The shortest side of the box base, which is perpendicular to the length, is measured to determine width.

Height: Measuring the distance between the base of the box to the top of the box is called height.

How to Measure the Volume of a Box?

It is important to measure the volume or cubic size of a box to calculate the right dimensional weight, helping brands with shipping products without any hassle. To calculate the volume of a box, you need to take the three dimensions of the box: length, width, and height. The formula to calculate volume is as follows:

Volume = Length x Width x Height

For example, a standard shipping box has 16” length, 12” width, and 12’ in depth/height. The above formula will be applied accordingly (Volume = 16 x 12 x 12). You will know that a standard shipping box’s volume will be 2,304 cubic inches.

What are 2D or 3D dimensions?

Two-Dimensional Boxes: A two-dimensional box is a flat shape that has only 2 dimensions, length and width, and no depth. Items such as photographs, canvas, and legal documents are shipped in two-dimensional packaging.

Three-Dimensional Boxes: A 3-dimensional (3D) box is a solid object with length, width, and depth, such as a cube or a rectangular prism, and has volume. Items such as shoeboxes, cereal boxes, and tissue boxes are all common examples of three-dimensional boxes encountered in everyday life.

Order of Length Width Height

The standard order to measure a box’s dimensions is Length x Width x Height. However, the length, width height measurement order sometimes depends on whether the box is horizontal or vertical.

-

Height Width Length Order

The height, width, and length dimensions can vary depending on what type of product packaging you want to measure. Every brand has a different size guide and follows the measuring techniques accordingly. They measure height first, followed by width and Length. This order is often used for vertical boxes.

-

Height Length Width Order

Height, length, and width order is followed for the object or box in a horizontal shape. You can start measuring the height first, and then the length and width. The order could be different, but the formula will apply in the same way to calculate the cubic size and dimensional weight.

-

Length Height Width Order

If you see the box from the side view, you will follow Length, Height, Width order. Look at the box from its front panel and turn it to 90 degrees. Now start measuring the length, which is usually smaller than the height and width.

Length Vs Width

If we talk about cubes and rectangular prisms, length and width are at right angles to each other. From the front, both these dimensions combine to give a two-dimensional image to objects. The length and width of product boxes decide how long and wide products can be packed inside the packaging boxes.

Width Vs Height

Width and height are also at right angles to each other. However, the front view hides the height of a cuboid or rectangular prism box. These dimensions combine to decide the depth and width of items that can be accommodated in the packaging boxes.

Height vs Length

Like width vs height, length also shadows the height of a cube from the front view. Dimensions of products from left to right and front to back are determined by the height and length of the packaging boxes.

Difference Between Length, Width, Height

Let’s take an example of a cereal box to understand the difference between length, width, and height. Look at the box from the front. The bottom, tallest part of the cereal box is its height. Keep the box straight and measure from the right to the left, which is its width.

Turn the box at 90 degrees and see the side panel. The side panel of a cereal box is approximately 2”, which is its depth or length. The difference between length, width, and height lies in how tall or wide these parts are. For example, a standard cereal box is 12 inches in height, 7.5 inches in length, and 2 inches in width.

Measuring Internal Dimensions of a Box

Since you have explored finding three dimensions of your box, there is one crucial aspect to keep in mind. That is, you should always measure the internal dimensions of your box. This is because the box dimensions of the industry standard box depend on internal measurements instead of external ones.

The reason for relying on internal measurements is that they fit your products snugly. Plus, internal dimensions are more precise for both the manufacturer and your product. Though it might appear easier to measure the outer measurements of the box, internal dimensions are what matter for your custom packaging box sizes.

Tips to Measure the Length, Width, and Height of a Box Correctly

You need to make a checklist of things you need to measure the box’s dimensions. Get supplies ready, like measuring tape, a small ruler, and a notepad to write the dimensions to measure the box. Start measuring from the tallest side, from top to bottom, to measure the height of a box. Then move to the width and length, respectively. Use a small ruler to measure small mailer boxes and a large yardstick for large boxes.

Tools for Measuring Length, Width, and Height

Measuring boxes accurately is essential when it comes to the snug fitting of products inside. To do so, you need accurate tools that help you create boxes of perfect length, width, and height. Some tools you can leverage to measure the dimensions of your packaging boxes are listed here:

- A caliper to measure thickness.

- Rulers to measure length, width, and height separately.

- Flexible measuring tapes to measure the perimeter of the boxes

How to Note the Dimensions Length, Width, Height of a Box?

When measuring a box, following the correct order is important to ensure precision. Wondering what the correct order of a box's dimensions is? The following is the correct order you should follow:

Length x Width x Height

Length – the widest length of the box from left to right

Width – the shorter side form the box's front view.

Height – the measurement from the box's top to bottom.

For example, a mailer box’s dimensions: 16 inches in length, 12 inches in width, and an 8-inch-high box.

Note it down as:

Length: 16 inches, Width: 12 inches, Height: 8 inches

You can apply this correct measuring order to a square or a rectangular mailer box that is often used for shipping, storage, and display.

Final Thoughts

In this blog, you have found how to measure the dimensions of your box and calculate its volume. Also, develop a better understanding of the significance of measuring internal dimensions to get the right packaging size for your products. In case you want custom-sized boxes for any product, contact OXO Packaging to enjoy hassle-free packaging with precisely sized boxes

In length, width, or height, first comes length, followed by width, and then height. Hence, the order becomes l x w x h.

To accurately measure the height of a box, you need to determine its length and width as well. Start by measuring the longest side as the length, the shortest side as the width. Afterwards, you can differentiate the perpendicular side as the height.

The formula l x w x h represents the calculation of volume for a three-dimensional object like a rectangular prism or a box.

The standard order for dimensions is Length x Width x Height (L x W x H). When measuring a box, length is typically the longest side of the base, width is the shorter side of the base, and height is the vertical distance from the base to the top.