.webp)

In Stock

Crafted from premium cardboard, our tuck flap boxes are designed for durability and strength. The sturdy construction ensures that your products are well-protected while maintaining a sleek and professional appearance.

.webp)

Quality of the product was outstanding and we loved the result! We had a small mismatch with one of the images on the boxes but Jason was great at und...

Date of experience:

August-22-2024

Katie is a rockstar! She has ensured an easy ordering process and the custom boxes I ordered are perfect. Customers love the quality....

Date of experience:

August-01-2024

Katie made the entire process of design and ordering a breeze! The finished product is beyond expectations! Definitely takes our soap business up seve...

Date of experience:

October-04-2024

Our company had been looking for new packaging for one of our products for quite a while. I am so glad we came upon OXO Packaging. From the start, the...

Date of experience:

June-13-2024

.webp)

Great service once I placed order. James worked very diligently for meeting the timeline. The process was transparent as far as shipping was concerned...

Date of experience:

April-05-2024

.webp)

We hired Oxo Packaging to design several of our product boxes & labeling and what a great decision that turned out to be not only did they provide gre...

Date of experience:

December-15-2023

My experience with oxo packaging has been awesome. They are responsive and prompt and my boxes are perfect. Thank you to Ross Morgan my packaging cons...

Date of experience:

May-19-2021

i have been in business for 5 years and always thought it would be to expensive to have small batch boxes made. Surprise Surprise, a member from my so...

Date of experience:

April-08-2024

OXO Packaging, especially Harry was an excellent decision. I went from not knowing what I wanted to go with to understanding all of my options and pla...

Date of experience:

July-17-2025

ID 1045

Payment Methods

Tuck flap boxes can be customized with multiple options, like using high-end material, modern printing technology, and adding styles and finishes to your product packaging solution. This will help you present your brand differently.

More Than +5000 Satisfied Clients Worldwide What We Give Create Custom Boxes Quick and Easy Design

Design

Get your custom boxes made in the required size, shape, and style.

Print

Print

Upload your artwork and get it superbly printed the way you want.

Get it done

Get it done

Order any quantity, enjoy a wholesale price, pay no extra for die plates.

.webp)

|

Box Style |

Tuck box |

|

Dimension (L + W + H) |

All Custom Sizes & Shapes |

|

Quantities |

No Minimum Order Required |

|

Stock |

10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

|

Printing |

No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

|

Finishing |

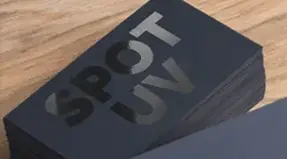

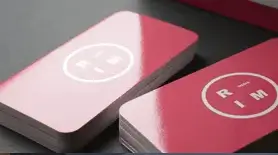

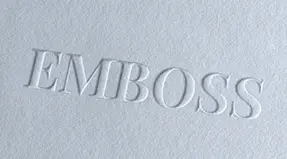

Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

|

Included Options |

Die Cutting, Gluing, Scored,Perforation |

|

Additional Options |

Eco-Friendly, Recycled Boxes, Biodegradable |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling (On request) |

|

Turnaround |

4 - 8 Business Days, RUSH |

|

Shipping |

FLAT |

Presenting your products in stylish packaging, like tuck flap boxes can boost your brand value and grow your sales. Experience customization services of OXO Packaging to craft your product packaging to help your customers memorize your brand.

.webp)

Instant Quote

Fill this form if you are not sure about the dimensions.

The different specifications and features of the material are considered while deciding the production of the tuck flap boxes, just like producing other packaging boxes. Following are the material choices that can be the best of the choices according to the requirements of your products:

C1S or coated one-side paper is one of the priority options for your tuck flap box packaging. The material is coated from one side with gloss or matte to make the surface protected, while the other side remains as it is.

Corrugated paper or corrugated cardboard is used for the increased strength and durability of these tuck flip boxes to provide extra protection to the products packaged in these boxes.

Paper pulp is the raw material for colored paper which is made by adding dyes and pigments in the process of making color paperboard. This is considered a good choice for making strong and attractive packaging paper for tuck-end boxes.

The best material choice is highly dependent on the requirement of packaging. However, heavy cardstock or kraft paper can be considered the best choice for tuck flap boxes.

Tuck boxes are specially designed focusing on functionality first, adding convenience and establishing brand identity along with the basic features of packaging. The styles and shapes of these tuck boxes are many. Among the popular and trending choices, here are a few for your attention to decide for your tuck box packaging or grab an idea for unique tuck boxes.

Reverse tuck boxes are designed to be easy to print at a lesser cost as compared to the other packaging choices. These boxes are designed with different opening and closing mechanisms. Flap reverse tuck boxes are opened and closed from the opposite side of the boxes at the top or the bottom.

Straight or front tuck boxes are opposite to the reverse tuck box packaging. These boxes are designed to open and close from the same side, front side, of the boxes. Straight flap tuck boxes provide convenience in opening and closing of these boxes from the front side.

These top tuck auto bottom boxes provide convenience to open or close these boxes after packing the content. These boxes can close from the bottom automatically without any difficulty or special attention and care.

Roll-end tuck-top boxes are another type of tuck-box packaging. These boxes in contrast with other tuck boxes provide a closure feature that helps more protective packaging for your products. The different closing style is with the long flap that closes from the front covering the top of these boxes.

Tuck flap boxes are the popular choice for product packaging due to compelling reasons. These reasons include but are not limited to the following:

Personalized packaging is more result-oriented than generic packaging that lacks attraction and attention-grabbing features. Custom packaging allows you to maximize your product elevation, trust, and credibility, and a distinct and appealing presentation of your brand and products. Here is how you can gain the customization advantage for your brand:

Getting an edge in your market with the flood of your competitor’s products on the retail shelves and online marketplaces, OXO Packaging can help you create a strong brand identity with our valuable offerings. Highly expert professionals can help your brand packaging with pleasing designs through the crafting of your product packaging to set you apart from your competitors with amazing benefits for your brand.

Experience the undeniable worth of packaging services to gain an unbeatable advantage for your custom tuck flap boxes.

Straight and reverse tuck boxes both are tuck boxes and have the same mechanism in opening and closing these boxes except the opening of these boxes. Straight tuck boxes are opened from the front side. On the other hand, reverse tuck boxes provide an opportunity from the reserve side of these boxes.

Rachel has been a delight to work with from start to finish, responding to my many questions and requests. She worked well with my graphic designer to...

Date of experience:

May-14-2024